Flexible PCB definition:

FPC for flexible PCB,Flexible PCB is made of flexible insulation substrate PCB, with many advantages that hard printed circuit boards do not have. For example, it can be bent, wound and folded freely, arranged arbitrarily according to the requirements of spatial layout, and move and expand arbitrarily in three-dimensional space, so as to achieve the integration of component assembly and wire connection. The use of FPC can greatly reduce the volume of electronic products, suitable for electronic products to the direction of high density, miniaturization, high reliability development needs. Therefore, FPC has been widely used in aerospace, military, mobile communication, laptop, computer peripherals, PDA, digital camera and other fields or products.

Advantages of flexible PCB:

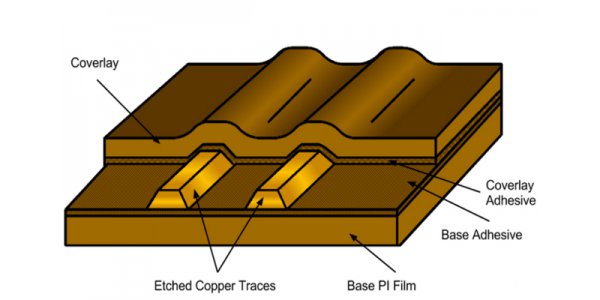

1).FPC also has the advantages of good heat dissipation and weldability, easy to install and connect, and low comprehensive cost. The design of combining soft and hard also makes up for the slight shortage of flexible substrate in the bearing capacity of components to some extent.2).FPC can be divided into one - sided, two - sided and multi - layer board. The substrate used is polyimide copper clad plate. This material has high heat resistance, good dimensional stability, and the covering film with good mechanical protection and good electrical insulation properties is pressed into the final product. The surface and inner layer conductors of the double-sided and multi-layer PCB are metallized to realize the electrical connection of the inner and outer layer circuits.

3).The functions of FPC can be divided into four types: Lead Line, Printed Circuit, Connector and IntegraTIon of FuncTIon, which are used for computers, peripheral auxiliary systems, consumer appliances and automobiles.

1. Flexibility and reliability of flexible PCB:

1). Currently, four kinds of flexible circuit boards are prevailing: single-sided, double-sided, multi-layer and rigid-flexible combination. "A single flexible board is the lowest cost," Friedman says. When the electrical performance requirements are not high, and can be single-sided wiring, should choose a single-sided flexible plate. This most common form has found commercial applications, such as jet cartridges for printers and memory for computers. The single-sided flexible plate has a layer of conductive graph etched by chemical etching, and the conductive graph layer on the flexible insulating substrate is calendered copper foil. Insulation substrates used for flexible assembly may be polyimide (Kapton), polyethylene terephthalate (PET), aromatic amide fiber paper (Nomex), and polyvinyl chloride (PVC).2). The double-sided flexible plate is a conductive pattern etched on two sides of the substrate. Metallized holes connect the two sides of the insulating material to form a conductive path to meet the design and use of flexural function. The covering film can protect the single and double sides of the wire and indicate the placement of the element.

3) multi-layer flexible board is to laminate three or more layers of single-sided flexible circuit board or double-sided flexible circuit board together, and form a metal hole through drilling and electroplating to form a conductive path between different layers. In this way, no complicated welding process is needed. Although the number of conductive layers designed for this flexible type can be unlimited, the interaction of assembly size, number of layers, and flexibility should be taken into account when designing the layout to ensure assembly convenience.

4). The traditional rigid-flexure plate is composed of the selective strata pressed together by the rigid and flexible substrates. The structure is compact, forming conductive connection with metallized holes. Considering the reliability and price factors, the factory should try to maintain as few layers as possible.

5) the flexible circuit board industry is in a small scale but rapid development. Polymer thick film (PTF) is an efficient and low-cost process for producing circuit boards. The process is to selectively screen conductive polymer inks on an inexpensive flexible substrate. Its representative flexible substrate is PET. The PTF conductor includes a silk-screen metal filler or a toner filler. The PTF itself is clean and USES lead-free SMT adhesives without etching.

6). There is also a flexible circuit board of mixed structure, which is also a kind of multi-layer board, but the conductive layer of the multi-layer board is made up of different metals. This hybrid structure is mostly used in the case of the relationship between electrical signal conversion and heat conversion and the low temperature where the electrical properties are relatively demanding. In this case, the flexible hybrid circuit is the only feasible solution.

7). Whether the composition of these flexible circuit boards can save costs and make the best use of them can be evaluated by the convenience of the design of internal connection and the total cost. "The overall approach to interconnect is different. Portable computers are located in the x-y direction. The printer is in rigid-flex PCB form. These products are made of different materials at different prices to reduce the cost of each inner lead. Each design is typologically evaluated to achieve the best performance-to-price ratio.

2. Economy of flexible circuit board:

1). If the design of the circuit is relatively simple, the total volume is not large, and the space is suitable, the traditional internal connection method is more cost-effective. If the circuit is complex, handles many signals, or has special electrical or mechanical properties, flexible circuit boards are a good design choice. One of the potential cost savings of flexible materials over rigid materials is the elimination of connectors.2). The high cost of raw materials is the main reason for the high price of flexible circuit board. Despite its expensive and troublesome raw materials, DiPalermo still believes that the ability to fold, bend, and assemble multiple layers of panels will reduce the overall size of the components, reduce the materials used, and reduce the overall cost of assembly.

Application of flexible PCB:

1). Mobile phone:Emphasis on flexible circuit board light weight and thin thickness. Can effectively save product volume, easily connect the battery, microphone, and button into one.

2). Computer and LCD screen:

Use flexible circuit board for integrated circuit configuration, as well as thin thickness. To convert digital signals into pictures and display them on an LCD screen;

3).CD player:

Emphasis is placed on the three-dimensional assembly characteristics and thin thickness of flexible circuit boards. Turn your bulky CD into a portable companion;

4). Disk drive:

No matter hard disk or soft disk, they all rely on the high softness of FPC and the ultra-thin thickness of 0.1mm to complete the fast data reading. Whether it's a PC or a NOTEBOOK.

5). Latest usage:

Mount circuit for hard disk drive (HDD, hard disk drive) (Su print ensi. Components of n cireuit) and xe package board;

Wireless charging coil array can concentrate electromagnetic energy in a certain area, reduce the consumption of space transmission, and improve the efficiency of energy conversion.