1).PCB manufacturing is now at the heart of current global technology trends. As technology evolves rigorously, as global market trends become dynamic, and as customer preferences and demand for unique electronic products change, electronic instruments and components are demonstrating the pace of innovation every other day. Even in the case of complex critical PCB layout requirements, electronics manufacturers and PCB manufacturers share the same concern for reliable, high quality, and low cost electronic solutions. A recent growth trend in PCB manufacturing is the use of heavy copper in PCB manufacturing. This paper reveals the richness of heavy copper used in printed circuit board manufacturing. In addition, it provides technical details for manufacturing PCBS using heavy copper substrates.

2).In order to meet the growing needs and preferences of customers in different markets, the trend of using heavy copper in PCB is becoming a "good show" in the current technology implementation world. When we talk about printed circuit boards, they have applications in every aspect of human life. From telecommunications, healthcare, automotive, defense, aerospace, military to renewable energy, transportation, industrial sectors and many other leading industries. On the other hand, the demand for faster, compact, safe use of products as well as higher efficiency and high power performance of high-tech electronic machinery and appliances is the customer's desire to introduce new technologies every other day to continue to move forward. This puts the PCB industry at the forefront of innovation and transformation. Whether it is heat dissipation, high speed, high frequency or other key design requirements, heavy copper in PCB manufacturing has demonstrated high performance output.

3).PCBS are constructed from heavy copper using a fine combination of copper plating and copper etching processes. As thin sheets of copper foil, these layers are made from electrical circuits. In addition, copper etching technology enables the elimination of unwanted copper and copper plating techniques to optimize the copper thickness of trace lines, solder pads, surfaces and boreholes on the PCB. The final lamination of the middle layer of the circuit board is completed using an epoxy substrate. These heavy copper PCBS are made from thermal layers and are best suited to multilayer PCB construction. In short, a thick copper PCB is made with a large amount of finished copper in the inner and outer substrates of the PCB, also known as lamination.

2.Heavy copper PCB manufacturing process:

(1) most suitable for compact electronic solutions, as it can remove or allocate minimal space for cooling fans or radiators, thus taking up less space.

(2) high load flow.

(3) high temperature resistance.

(4) use of heavy copper substrate, with high durability.

(5) easy to transfer heat to the external radiator.

(6) high quality and repeatability can destroy the normal PCB thermal cycle in a few seconds.

(7) it is very feasible in harsh environment.

(8) it has a high tolerance to thermal strain.

(9) the perfect combination of electroplating technology and copper etching technology is adopted to obtain negligible bottom cutting and straight edge wall.

(10) proved rough, tough, low distribution impedance.

(11) the heavy copper in the circuit board can also be connected with the standard circuit.

(12) the use of heavy copper plating technology, can produce a large current circuit, help to observe simple and compact beard structure.

(13) achieve high reliability of electronic performance by using heavy copper PCB layout or extreme copper PCB.

(14) the heavy copper concept is now successful and can even be mixed with standard properties on a single circuit board. PowerLink is well known.

(15) the use of heavy copper in PCB manufacturing can reduce the occupied board area and reduce the number of layers on the circuit board.

(16) increase the mechanical strength hole and connector position of the coating.

(17) it is possible that you do not repeat the copper PCB layout of special materials under high temperature conditions.

(18) another major reason for the high utilization rate of heavy copper PCB is the reduction of extremely complex cable bus configuration. With these abundant heavily copper PCBS, researchers are moving toward an effective approach to implementing unique PCB layouts to meet complex requirements, making them more cost-effective, and providing high-quality PCB manufacturing.

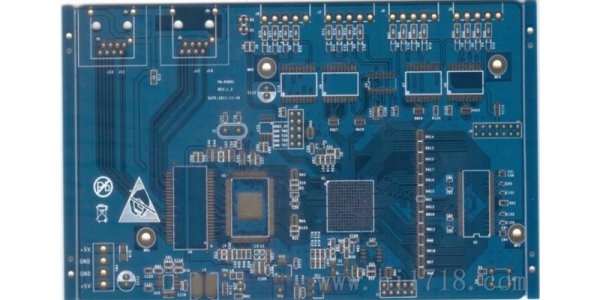

3.Introduction to manufacturing method of thick copper PCB:

1).Thick copper PCB, including several pieces of cascading set of core board, one of the most outer layer of the two pieces of core board outside set with copper foil, copper foil and between core board, core board and core board between the first half has curing, core board including thick copper layer, each side has its core thickness of copper layer is adjacent to the second half of the curing, described in the second half of curing on a chip with the corresponding thickness of copper layer graphics instead of gong to take, described in the copper foil and core board described by more than the first half cure piece, the second half cure bonding connection.

2).The thick copper PCB, near the location of the core thickness of copper layer is set in the second half, curing and curing in the second half on a chip is equipped with corresponding graphics instead of gong to bring thick copper layer, namely gong PP lamination design, core board after pressing large filling adhesive thickness without copper area to: thickness of copper thick - pressing gong PP theory, core board with no copper resin filling was increased greatly, which can effectively solve bigger without copper thick copper PCB area factors bring underfill resin flow in the process of pressing the pressing hole and the thickness of inequalities.

3).Modern electronic products have increasingly complex electrical characteristics and the resulting high requirements for power supply and signal, so in the production process, the number of layers of ultra-thick copper PCB board is increasing. Thick copper plate also known as copper foil laminate, generally the outer finish copper thickness ≥2oz is defined as thick copper plate. Thick copper plate is mainly used for power supply products, when the voltage and current are relatively high, such as copper thickness ≥6oz circuit board is mainly used for the manufacture of wireless charging coil power board. It is the basic material of PCB, also known as the substrate. According to normal process because of the thick copper plate making pressing production or made of cushion, due to the medium in the process of production, plank and technological process, prone to detonation board, layered, become warped plate, pressure is insufficient, excessive size and inequality and its technical difficulties are pressing to fill glue, both inside and outside layer etching, prevent weld printing, so we need to improve the existing technology.