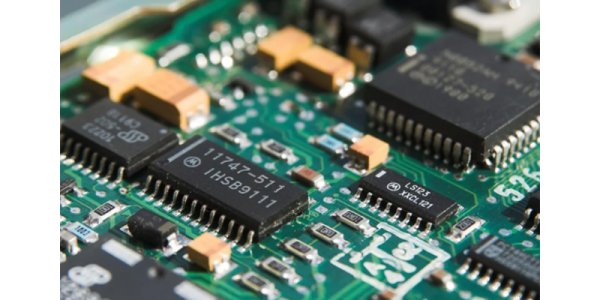

As for the selection of PCB as the board substrate, FR4 epoxy fiberglass wiki board is used for electronic products like, polyimide fiberglass wiki board is used for high ambient temperature or flexible circuit board, and polytetrafluoroethylene fiberglass wiki board is used for high-frequency circuit. For high heat dissipation requirements of electronic products should be used metal substrate.

(1). Substrate with high glass transition temperature (Tg) should be appropriately selected. Tg should be higher than the operating temperature of the circuit.

(2) low coefficient of thermal expansion (CTE) is required. Due to the inconsistent thermal expansion coefficient of X, Y and thickness direction, it is easy to cause PCB deformation, which will cause metal hole fracture and damage to components.

(3) high heat resistance is required. PCB is generally required to have a heat resistance of 250℃/50S.

(4). Good flatness is required. PCB warping degree of SMT is required to be <0.0075mm/mm.

(5) in terms of electrical performance, materials with high dielectric constant and low dielectric loss are required to be selected for high-frequency circuits. Insulation resistance, voltage - resistant strength, anti - arc performance to meet the product requirements.

1).First of all, high Tg means high heat resistance. With the rapid development of the electronic industry, especially the electronic products represented by the computer, towards the development of high function and high multi-layer, the higher heat resistance of PCB substrate material is needed as an important guarantee.

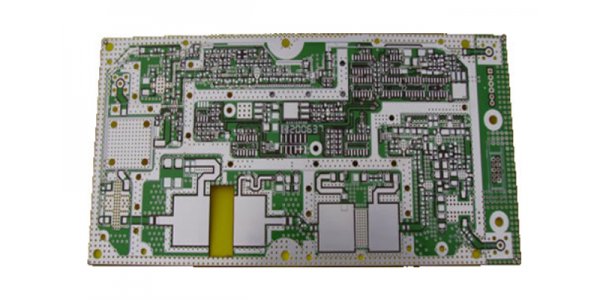

2).With the emergence and development of high density installation technology represented by SMT and CMT, PCB is more and more inseparable from the support of high heat resistance of substrate in the aspects of small aperture, fine wiring and thin type.

3).PCB substrate material under high temperature, not only produce softening, deformation, melting and other phenomena, but also show in the mechanical, electrical characteristics of the sharp decline (I think we do not want to see their own products appear in this case).

4).Therefore, the difference between general fr-4 and high Tg fr-4 is that under the hot state, especially under the heat after hygroscopicity, the mechanical strength, dimensional stability, adhesion, water absorption, thermal decomposition, thermal expansion and other conditions of the material are different, and high Tg products are obviously better than ordinary PCB substrate materials.

High-frequency PCB definition:

High Tg refers to high heat resistance. Generally, the boards of Tg are over 130 degrees, high Tg is generally greater than 170 degrees, and medium Tg is about greater than 150 degrees. Generally, PCB printed boards with Tg≥170℃ are called high Tg printed boards. With the rapid development of the electronic industry, especially the electronic products represented by the computer, towards the development of high function and high multi-layer, the higher heat resistance of PCB substrate material is needed as an important guarantee. With the emergence and development of high density installation technology represented by SMT and CMT, PCB is more and more inseparable from the support of high heat resistance of substrate in the aspects of small aperture, fine wiring and thin type.

With the improvement of Tg of substrate, the heat resistance, moisture resistance, chemical resistance and stability of PCB will be improved. The higher the TG value, the better the temperature resistance of the plate, especially in lead-free process, the higher the TG application is.

Therefore, the difference between general fr-4 and high Tg fr-4 is that under the hot state, especially under the heat after hygroscopicity, the mechanical strength, dimensional stability, adhesion, water absorption, thermal decomposition, thermal expansion and other conditions of the material are different, and high Tg products are obviously better than ordinary PCB substrate materials.

High frequency Tg PCB selection method:

Tg value refers to the glass conversion temperature of the CORE, which you can understand as the softening temperature of the plate.

For designers, choosing Tg values of PCB depends on the working temperature or environmental conditions of PCB of the products involved. Here we must first talk about the common Tg values:

1).135~140 ℃, which is the Tg value of common fr-4 plates;

2).About 170 ° c, this is the Tg value of the plate in the fr-4 high-temperature ladder section;

3).About 260 ℃, which is the Tg value of polyimide material;

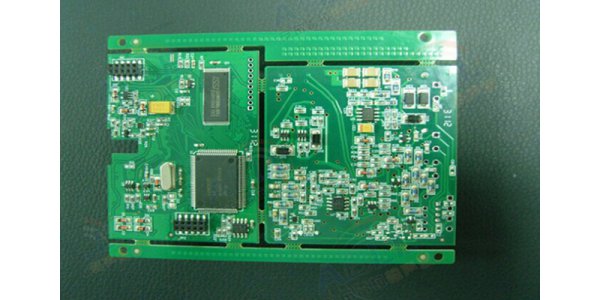

According to the temperature environment of different products in the above which range, can be assigned to the seat. If some experienced designers will consider a temperature margin of about 40°, such as the temperature environment of about 100 °, they can consider the Tg plate of 134-140 °. If it is a safe product level (24 hours continuous trouble-free work requirement), consider raising a gradient for selection.

High Tg PCB, including substrate and cover on the surface of the substrate, copper clad, whose character is: the substrate including the middle glass fiber cloth layer and set in the middle on the surface of the glass fiber cloth layer on both sides of the hot plasticity resin mixed plate, it is hot plasticity resin mixed plate and intermediate between glass fiber cloth layer is equipped with flame retardant mixed plate.

Why can't ordinary TG mix with high TG:

1).Due to different Tg values of material characteristics, pressing high Tg values with low Tg values will result in insufficient curing time and lead to plate explosion. Pressing down high Tg values with high Tg board parameters will result in excessive amount of glue flow, resulting in thin plates.

2).TG refers to the glass state transition temperature, which is the glass transition temperature of the plate under high temperature. Generally, the TG plate is over 130 degrees, the high TG is generally greater than 170 degrees, and the medium TG is about 150 degrees.

3).The higher the TG value, the better the temperature resistance of the plate, especially in the lead-free process, the higher the TG application is more, because the glass transition temperature of the high TG and the bottom TG are different, the higher the TG, the better the temperature resistance.