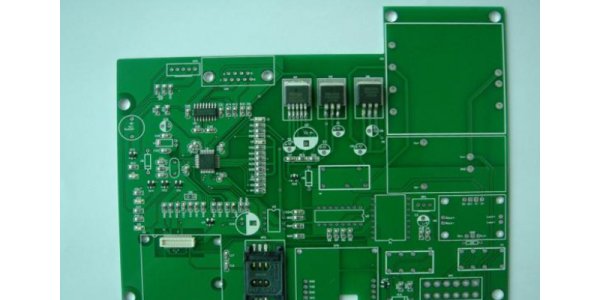

PCB is an important electronic component, the supporting body of electronic components, and the carrier of electrical connection of electronic components. Because it is made by electronic printing, it is called "printed" circuit board. The following mainly introduces the PCB processing process:

1. Opening principle: cut aniseed into small pieces according to the size required by MI.2. Lining: dry film or ink filters, membrane exposure at shadow etching back lining erosion is one - a graphic transfer process, through the use of film negative, ink/dry film medium under the irradiation of ultraviolet light, such as the customer need line graphics, the layer of the substrate, then don't need the copper foil etching, eventually make the inner conductive lines.

Pretreatment: the inner layer of the dry film of the grinding plate is etched for internal inspection + the surface of the copper plate is roughened to facilitate the increase of the bonding force between the plate surface and the drug film + the cleaning of the plate surface, remove the sundry film of the plate surface and the covering ink of the copper foil and the covering of the copper foil.

3. Pressing process: Browning, plate-arranging, pressing, X-ray punching, hole and gongs.

4. Drilling operation: the function of drilling is to produce a conductive channel on the circuit board that allows the completion of the post-operation to connect the upper/lower part of the circuit board or between the intermediate circuit layers.

1). Copper precipitation: deposit a ~ layer of conductive copper layer on the hole wall insulated by the circuit board, and connect it with the inner layer.

2). Outer dry film: stick the dry film to expose the impact.

3) graphic electroplating or plate electroplating: function: increase the copper thickness of the hole line and surface of the circuit board to meet the customer's requirements.

4). Outer etching: decoating: remove or dissolve unwanted dry film from the surface of the plate by using strong alkali to dissolve or peel the dry film.

5). Etching plate: use the oxidation of divalent cuprammonium complex and ions to remove unwanted copper from the plate.

6) tin removal: the use of nitric acid in tin removal water and tin reaction to dissolve the tin coating to return tin from the plate.

7). Outer inspection: AOI&VRS absorbs the image of the circuit board through CCD scanning, compares it with CAM standard graphics by computer, and processes the logic of the design specification, marks the bad points on the circuit board and sends the coordinates of the bad points to the VRS, and finally confirms the position of the bad points.

6. Wet film process: the main process stations are: the molding of the outer line plate and road surface, printing on a layer of photosensitive ink, so as to cure, so as to protect the outer layer and insulation of the circuit board, pre-processing grinding plate, ink printing, frying furnace exposure shadow, character printing.

7. Surface treatment process: according to the customer's requirements, the exposed copper surface of the circuit board is processed with one layer.

The main processing process is:

1). spray tin: spray a "layer of weldable tin on the copper surface with hot air welding process.2). Tin sinking: using the principle of chemistry, the tin is deposited on the plate surface by chemical treatment.

3) silver precipitation: silver is deposited on the plate surface by chemical principles.

4). Gold deposit: deposit gold on the plate surface by chemical principle.

5). Gold plating: using the principle of electroplating, the gold plating is made on the plate surface by current and voltage control.

6). Anti-oxidation: apply an anti-oxidation chemical to the surface of the board using the principle of chemistry.

8. Molding process: mainly according to the customer's requirements, the formed circuit board is processed into the customer's required size shape.

9. Open short circuit test and inspection: it is mainly to check the open circuit and short circuit inspection of the circuit, as well as the quality of the board with the eye.

10. Packaging and shipment: packaging the inspected and qualified boards for final shipment to the customer.

PCB processing comparison:

1.board size is different: large board general single piece of shipment, fork is also a waste, should do scrap processing.

2.Small size board usually puzzle shipment, puzzle is a puzzle in will have a bad board, to bad board will adopt the method of cross to show board is useless, we usually don't accept to cross board, but considering the idea of number, 100 pieces of a puzzle, only one is bad, to cross it, than this column is generally not more than 5%, single if two makeup, there is a poor, that does not cross rate is 50%, because the board is larger, spell only two.

3.When making the board and the board factory to explain how much of the white fork rate can be accepted, or more fork on the whole plate scrap.

4.Because printed circuit board is not general terminal product, so on the definition of the name is a little confused, for example: the mother board for personal computers, called the motherboard, but not directly called the circuit board, although there is a board in the motherboard, but not the same, so the evaluation of the industry about the two can not say the same.

Another example: because there are integrated circuit parts loaded on the circuit board, so the news media called it IC board, but in essence it is not the same as the printed circuit board. When we talk about printed circuit boards, we mean bare boards -- circuit boards without components.

PCB comparison material comparison:

Along with the development of The Times, social change is more and more frequent, the development of electronic industry is becoming more and more fast, PCB outgoing SMT processing mode are less and less used by electronic product research and development company, people began to looking for the right PCBA for overall manufacturing solutions provider, electronic products in the research, development, production and sales have to careful accounting of the procurement of raw material in the whole process cost, inventory cost, personnel management, market opportunity cost, etc., PCB outgoing SMT processing and PCBA for material cost comparison, you will find that, The PCBA model reduces the overall cost of PCBA electronic manufacturing and greatly reduces the risk of the client. The professional things to professional people to do, the surface of the individual price is increased, but the actual overall cost is down.