In the electronics industry, the effect of humidity is a very troublesome thing. Whether transported in airy tropical areas or in humid areas, humidity is a significant contributor to electronics industry spending. Concerns about this failure mechanism have increased due to the increased use of humidity-sensitive components. But even if you know the failure mechanism, you still need to confirm the humidity sensitivity level of the component to avoid the risk, and then carry out the correct packaging, storage, and pretreatment.

To solve the humidity problem of components, AiPCBA has built a constant temperature and humidity warehouse of more than 1,000 square meters. It contains more than 100,000+ pieces of resistors, capacitors, inductors, diodes, transistors, crystal oscillators, chips, and other mainstream brand components from stock. Whether it is a prototype, small volume production, or big volume production, AiPCBA's factory warehouse can directly unload materials to the production line, reducing the time of waiting and the receipt of purchased materials. Learn more about AiPCBA’ s Parts sourcing.

But some SMD components need to be baked to remove the moisture inside and some do not. What is the moisture sensitivity level (MSL)? The following are common questions about baking moisture-sensitive / non-moisture-sensitive parts.

1. What is the hazard of the components getting wet? Which electronic components are exposed to moisture?

1) Moisture can oxidize the solder pins of parts, resulting in poor solderability.

2) If moisture enters the interior of packaged parts, such as IC packaged parts, when these parts undergo a rapid heating process, such as Reflow, the moisture and water molecules inside them will rapidly expand their volume due to heating. At this time, if moisture failure to effectively escape the inside of the packaged part will result in de-lamination due to the expansion of the volume of water molecules, and even popcorn from the inside of the part.

3) If the welding leg of the part has been oxidized, it is basically impossible to return the oxidized welding leg to the state before oxidation by rebaking, and it may be reprocessed by electroplating.

Therefore, the main purpose of baking is to avoid the existence of moisture inside the packaged parts, and the phenomenon of popcorn or de-lamination occurs during the rapid heating and high temperature process of reflow.

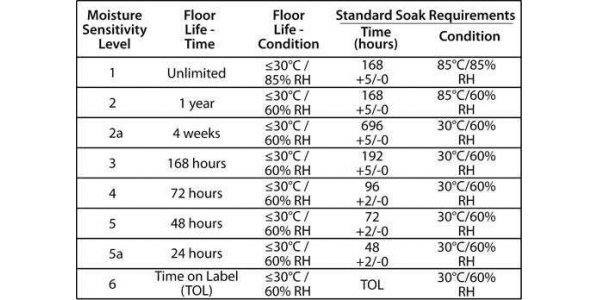

Let’s check the moisture sensitivity level (MSL) as below picture.

2. What kind of parts need to be rebaked?

In principle, as long as it is a packaged part (generally referred to as an IC part), especially a packaged part that needs to be reflowed, it should be re-baked if there is any doubt about moisture.

As to whether hand soldered parts or package parts subjected to wave soldering need to be baked if they are wet, there is no clear stipulation in J-STD-033B. Although the hand soldering and wave soldering operations are much cooler than the reflow soldering on the part body, if time permits, it is still recommended to bake wet packaged parts according to J-STD-033B. After all, The temperature during the operation is still far above the boiling point of water, and there is still a chance that the parts will be delaminated.

3. Can the reel be baked in the oven?

According to the provisions of 4.2.1 and 4.2.2 of J-STD-033B, the packaging of general moisture-sensitive parts must indicate whether the packaging is capable of withstanding high-temperature baking at 125℃ or low-temperature packaging exceeding 40℃. Generally, if it is not marked, it can withstand high temperature baking at 125℃.

If the packaging material is low-temperature packaging, you must remove all packaging when baking, and then reinstall the original packaging after baking. Regardless of whether it is high or low temperature packaging, the original paper and plastic containers (such as cardboard, bubble bags, plastic packaging, etc.) must be picked out before baking. The rubber band and tray are at high temperature (125℃). ) Must be picked out before baking.

4. Why do some manufacturers claim that their low-humidity drying boxes can prevent the moisture effects of moisture-sensitive parts, and what is the role?

According to J-STD-033B section 4.2.1.1 and 4.2.1.2, if the moisture sensitivity level (MSL) 2, 2a, 3 is exposed to the workshop for less than 12 hours, and placed at ≦ 30℃ / 60% In the RH environment, as long as it is placed in a dry packaging or a drying cabinet below 10% RH, after 5 times of exposure to the atmosphere, the floor life of the part can be recalculated without baking.

In addition, if the MSL 4, 5, 5a module is exposed to the workshop for less than 8 hours, and placed in an environment of ≦ 30℃ / 60% RH, as long as it is placed in a dry packaging or cabinet below 5% RH after 10 times of exposure to the atmosphere, floor life can be recalculated without baking.

Therefore, only some manufacturers claim that when the moisture-sensitive parts are unused after opening, they can be placed in an electronic drying cabinet below 5% RH to suspend or recalculate their workshop time.

However, the storage space of the drying cabinet is limited after all. It is recommended to open the drying package before using the parts to ensure that the parts will not be wet, and the temperature and humidity of the factory workshop should be controlled within 30℃ / 60% RH.

5. Can the desiccant be reused?

According to J-STD-033B Section 4.1.2, if the desiccant in the dry package is only exposed to the factory environment below 30 ° C / 60% RH, and the time does not exceed 30 minutes, the original desiccant can be reused. But the premise is that the desiccant is not wet or damaged.

6. Can parts be baked repeatedly? Is it better to bake as long as possible? Are there any baking restrictions?

According to J-STD-033B section 4.2.7.1, excessive baking of parts may cause the parts to oxidize or generate intermetallic, which will affect the quality of soldering and circuit board assembly. In order to ensure the solderability of the part, it is necessary to control the time and temperature of the part baking.

Unless the supplier has special instructions, the cumulative baking time of the part at 90 ℃ ~ 120 ℃ cannot exceed 96 hours.

If the baking temperature is below 90 ° C, there is no limitation on the baking time.

If the baking temperature needs to be higher than 125 ° C, the supplier must be consulted, otherwise it is not allowed.

In addition, the compound used in the gel of the IC package repeatedly undergoes high temperature (> Tg (glass transition temperature)), which will cause the material to deteriorate and become brittle, and the IMC originally formed inside the IC will accelerate its electrons under high temperature speed of migration. When the holes of the IMC increase, the original wire bond will easily fall off, causing quality problems such as open circuits. Therefore, it is still questionable whether the baking time is as long as possible, at least in the high temperature environment. .

7. Do non-moisture sensitive electronic parts also need to control moisture?

Do non-IC package parts have similar MSL specifications? For example: connectors, frequency components, passive components, etc. If these unpackaged parts are stored in the warehouse for more than one year, can they still be used? Or can I continue using it after baking?

IPC JEDEC J-STD-033's control of moisture sensitive parts (MSD) is basically only applicable to IC and other packaged parts. For other non-packaged electronic parts, the management and control of moisture is not necessarily required, but it is necessary to consider the possible effects and consequences of moisture on these electronic parts, but it can basically be divided into the following two aspects to consider:

1)Whether to use materials that easily absorb moisture.

Taking the connector as an example, if you use a resin such as PA66 Nilon that is easy to absorb moisture, you must pay special attention to the effect of moisture on the material. Such resin will become brittle after moisture absorption, especially after high temperature. If possible, try to replace the resin of PA66 with the resin of LCP, which can greatly improve its ability to resist moisture.

2)Is the solder foot plating exposed to air likely to cause oxidation and rust.

Moisture promotes the oxidation of most metal surfaces. If the surface treatment of the solder feet is tin or silver, or even bare copper (cooper), it is recommended to control the humidity to prevent oxidation.

Based on the above two reasons, it can only be said that whether or not electronic parts are controlled for humidity sensitivity depends on different parts (case by case).

8. The recommendations are as follows:

1) All parts requiring soldering should be stored in an environment with temperature and humidity control for 24 hours (at least in an air-conditioned room) to reduce the rate of moisture absorption and oxidation of the solder feet. Of course, it is better to put the dry bag in vacuum packaging, which is the cost consideration.

2) For some materials that are relatively easy to absorb moisture and parts that are oxidized by the solder feet, humidity-sensitive control is required. As for what moisture sensitivity level should be set, it depends on experience.

3) If these non-encapsulated parts are stored in the warehouse for more than one year, can they be used after baking?

This problem depends on whether the solder feet of the parts have been oxidized. It is recommended to use them for "weldability test". If the solder feet have oxidized and cannot eat tin, then baking is useless. The oxidation of metals is basically irreversible. Reaction, that is to say, re-baking cannot return the oxidized soldering leg to the state before oxidation, because the main purpose of baking can only remove moisture from the part.

If the weldability is ok, and you are still not sure if the moisture will affect the part, it is recommended to send the part for low temperature baking to remove the moisture.

Rapid Parts sourcing capability in AiPCBA

1)Intelligent spot materials storage warehouseAiPCBA has more than 2,000 square meters of constant temperature and humidity warehouses, and more than 100,000 kinds of resistors, capacitors, inductors, diodes, transistors, crystal oscillators, connectors, and other mainstream brand components are available in stock. Whether it is a prototype, small batch production or mass production, the factory warehouse can directly issue materials to the production line, reducing the waiting time and receipt of purchased materials.

2)Global Supplier Authorization Certification

In addition to its own standing materials, AiPCBA also connects with global distributors Digikey, Mouser, Arrow, RS, etc., as well as the API interface of spot inventory data of more than 800 domestic spot suppliers in China, to grasp the advantageous channels of material supply and inventory changes in real-time. Self-developed ERP system provides strong support for the supply chain management. The prototype quotation will complete the BOM quotation within 5 minutes at the earliest, and the factory's own materials will be released on the same day.

3)Professional technical support team

AiPCBA has an experienced component expert service team and a senior material supply chain team, providing professional replacement services for risky materials to help you reduce material costs and supply chain risks. The material cost of PCBA mass-produced products can be reduced by more than 50%.

3)Advanced component testing laboratory

AiPCBA has a 500-square-meter professional component testing laboratory and a professional testing engineer team in China, which supports several professional tests such as electrical performance of components, package opening, X-Ray testing, and anti-counterfeiting testing ensure the quality of each material. Qualified and from genuine channels.

Material risk management based on component big data.

4)Based on the big data of 60 million components of the self-developed FindIC electronic components search engine, AiPCBA can quickly identify risks such as the life cycle of manufacturers' components, early warning of production shutdowns, material shortages for distributors, price fluctuations, etc., and provide production shutdown and shortage materials. alternative device.

5)BOM material risk assessment based on big data.

AiPCBA has the world's first BOM analysis material identification matching technology based on artificial intelligence identification technology. You only need to upload the BOM file with one click, and you can complete 90% of the material matching and material recommendation within ten seconds. At the same time, you can also intelligently check the engineering evaluation of the BOM, accurately check the number of materials, warn of packaging errors, parameter conflicts, selection, risk of errors, material outages, etc.

Learn more about AiPCBA’s Parts sourcing.