Goldfinger: (Gold Finger or the Edge Connector) insert the Connector into a PCB card slot, with the Connector plug as PCB exports of foreign connection, make the bonding pad or copper contact with the corresponding position of splice feet to achieve the purpose of conducting, and bonding pad on the PCB this or copper plating nickel and Gold, for into Finger shape so called goldfinger. Chose Gold because of its superior conductive and oxidation resistance. Resistance to wear. But because the cost of Gold is very high so applies only to local gold-plated Gold Finger, etc.

Goldfinger categories:

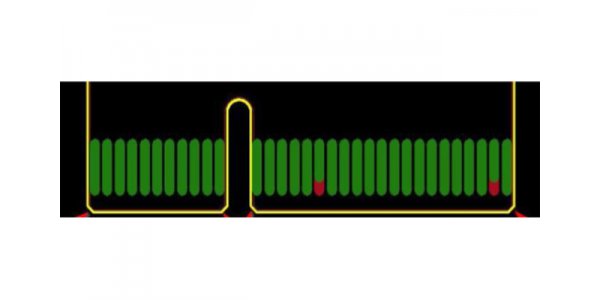

1). Regular goldfinger (flush finger); 2: long and short golden finger (i.e. uneven golden finger); 3: segmented goldfinger (discontinuous goldfinger).

2). Conventional goldfinger (flush finger): rectangular welding pads of the same length and width are arranged at the edge of the plate.

3). Network card, graphics card and other types of physical, goldfinger more, some small board goldfinger less.

4). Long and short goldfinger (that is, uneven goldfinger): rectangular welding pad with different lengths at the edge of the plate.

5). Storage, usb flash drive, card reader, etc.

6). Segmented goldfinger (discontinuous goldfinger): a rectangular solder pad with different lengths at the edge of the plate, and the front section is disconnected.

7). Features: no character box and mark, the conventional is to open a window for the resistance layer. Most of the appearance has grooves. Goldfinger part protruding out of the board edge, or near the board edge.

8). Notes: whether the lead can be drawn by electroplating, whether the hypotenuse is needed, whether the hypotenuse can be used, whether the inner layer of goldfinger position is covered with copper, the thickness requirements of goldfinger gold and nickel, the number of goldfinger counting rules, and the size specification of goldfinger.

3.Why do PCBS need goldfinger and heavy gold:

1).The advantages of the gold sinking process are that when printing lines, the surface deposition color is very stable, the brightness is very good, the coating is very flat, the weldability is very good. Generally, the thickness of gold deposit is 1-3 Uinch, which can be basically divided into four stages: pretreatment (oil removal, micro erosion, activation, and post-leaching), nickel deposit, gold deposit, and post-treatment (waste gold wash, DI washing, and drying).

2).However, in the production cost of the sinking process compared to other tin-spraying process, the cost is higher, if the thickness of the gold exceeds the conventional process of the plate factory, then the cost is more expensive, of course, if you have higher requirements for the board welding and electrical properties. Such as: your circuit board with the fingers need to sink gold, or the line width of the board/pad spacing is not enough, so it is best to do heavy + gold plating process for the finger, this circuit board welding is very good, circuit performance is also stable, bonding pad will not fall off, not bad contact, there will be no short circuit etc. Phenomenon, at the same time also is very shock drop, of course, we won't fall off the board.

3).Still have kind of circumstance is circuit board has goldfinger, but the board surface outside goldfinger can choose according to the circumstance to spray tin craft, namely spray tin + the craft of gold-plated finger, in circuit board line width and weld pad space are sufficient, the circumstance that weld requirement is not high, can reduce production cost effectively, do not affect the use of the board again. But if the board's wire width and welding pad spacing is insufficient, then this situation with the use of spray tin technology increased the production difficulty, will appear tin bridge and other short circuit will be more, will give cash finger often inserted strip, resulting in bad contact.

4.The definition of sunken gold:

Circuit board copper is mainly copper, copper solder easily oxidized in the air, it will cause solder bad or poor contact, electrical conductivity, that is, reducing the performance of the circuit board, then need to surface treatment of copper solder, heavy gold is gold plated, gold can effectively cut off copper metal air and prevent oxidation, so heavy gold is a way of dealing with surface anti-oxidation, is through the chemical reaction on the surface of copper covered with a layer of gold, also known as gold.

5.A brief introduction to goldfinger:

To put it bluntly, it's a brass contact, or a conductor. To be specific, it is the part connected with the memory slot on the memory strip, all the signals are transmitted by the goldfinger, there are a number of yellow conductive contacts, its surface is gold-plated and conductive contacts arranged like fingers, so called.

6.Details of goldfinger in PCB:

1).in order to increase the wear resistance of goldfinger, goldfinger usually needs to be plated with hard gold.

2).goldfinger needs chamfering, usually 45°, other angles such as 20°, 30°, etc. If there is no chamfer in the design, there is a problem. The 45° chamfering Angle in PCB is shown in the following figure:

3). Goldfinger needs to do the whole block of anti-welding window opening treatment, and the PIN does not need to open the steel net;

4). A minimum distance of 14mil from the tip of finger is required for the sink tin and silver welding pads; It is recommended that the pad should be more than 1mm away from the finger position during the design, including the through hole pad;

5). Do not coat goldfinger with copper;

6). All layers of the inner layer of goldfinger need to be copper whittled, usually with a width of 3mm; It can be done with half finger and whole finger.

7.The role of goldfinger in PCB:

1) the most important role of goldfinger is connection, so it must have good electrical conductivity, wear resistance, oxidation resistance, corrosion resistance.

2). The texture of pure gold (gold) is relatively soft, so goldfinger generally does not use gold, but just on the top of the plating of a layer of "hard gold (gold compounds)", this can not only get good conductivity of gold, but also can make it wear resistance, oxidation performance.