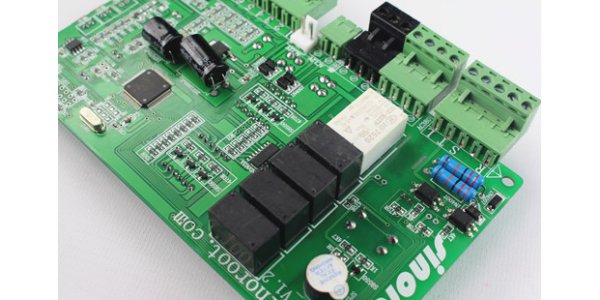

The PCBA processing supply chain is extremely long, including component procurement, circuit board production, SMT processing, THT processing, program firing, PCBA inspection and packaging logistics. PCBA inspection has produced ICT, AOI, X-Ray, Boundary-Scan, FCT and other testing methods. In view of the numerous IPC-A-610E standards, only a few major links need to be carefully grasped to achieve quality control on the basis of ensuring efficient production and operation.

1. ICT passed standards

The ultimate goal of PCBA inspection is that each PCBA board is tested before it leaves the factory. The most commonly used is ICT line inspection. As long as a very simple ICT test rack is made, the PCBA board can be 100% inspected. A PCBA board that passes the ICT test is considered to be part of the finished product with a 90% probability.2. FCT passed standards

FCT (Functional Circuit Test), generally refers to the functional test after PCBA is powered on, including: voltage, current, power, power factor, frequency, duty cycle, position measurement, LED brightness and color recognition, LCD character and color recognition, sound recognition, temperature measurement and control, pressure measurement and control, precision micro motion control, FLASH and EEPROM online programming and other functional parameters measurement. It refers to a test method that provides a simulated running environment (incentive and load) for a test target board (UUT: Unit Under Test) to make it work in various design states, thereby obtaining parameters of each state to verify the function of the UUT. Simply put, it is to load the UUT with the appropriate stimulus and load, and measure whether the output end response meets the design requirements.

(1) Manual control function test

(2) Test of semi-automatic control function

(3) Fully automatic control function test

The earliest functional tests were mainly manual and semi-automatic. Even now, for some simple functional tests of the board under test, manual or semi-automatic test solutions are sometimes adopted based on the consideration of simplified design and reduced production costs. With the rapid development of science and technology, in order to save production costs and improve production efficiency, most of the current functional tests are using fully automatic test solutions.

According to the type of controller, it can be divided into:

(1) MCU control mode

(2) Embedded CPU control method

(3) PC control method

(4) PLC control method

The system composition of PCBA function test is mainly divided into:

(1) System Control Center

(2) Control execution

(3) Parameter measurement section

(4) Data processing and output section

3. Other Inspection standards

3.1. Appearance standardsEach PCBA processing factory has an OQA factory inspection post. Visual inspection of the PCBA board before leaving the factory (partially assisting some professional instruments) to ensure that there are no obvious reliability issues, such as insufficient tin thickness and damage to parts and components.

3.2. Aging standards

In order to ensure that the PCBA board inspection standards are strict, the PCBA board needs to be spot-checked and subjected to aging tests. Generally speaking, it is frequently turned on and off or long-term power-on operation (based on the PCBA board burning program). In addition, professional instruments can be used to detect electromagnetic compatibility, power / voltage input and output signal stability, and so on. This test takes more time and can only be partially tested.