Differences between SMT Chip Technology and THT Plug-in Technology and their Characteristics

Posted: May 14, 2022

By: Bonnie

The characteristics of surface mount technology (SMT) can be reflected through the comparison with the traditional through-hole technology (THT). From the perspective of assembly process, the fundamental difference between SMT and THT is "stick" and "plug". The difference between the two is also reflected in various aspects of the substrate, components, component form, solder joint form and assembly process method.

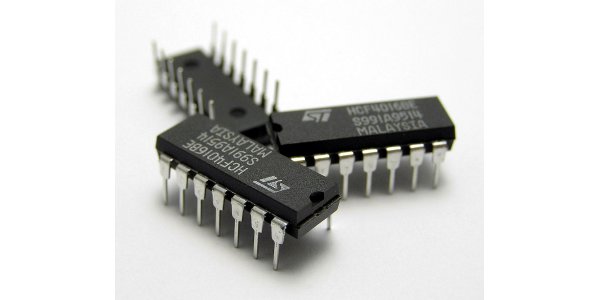

DIP package is a part package in the THT plug-in process, also known as Dual In-line Package technology. It is the simplest packaging method. It refers to integrated circuit chips packaged in dual in-line form. Circuits use this package, and the number of pins does not exceed 100. The DIP packaged CPU chip has two rows of pins and needs to be inserted into a chip socket with a DIP structure.

On a conventional THT printed circuit board, components and solder joints are located on both sides of the board. On SMT circuit boards, solder joints and components are on the same side of the board. Therefore, in SMT printed circuit boards, through holes are only used to connect the wires PTH on both sides of the circuit board. The number of holes is much smaller and the diameter of the holes is much smaller. In this way, the assembly density of the circuit board can be greatly improved.

2.SMT soldered PCBA has stable quality performance: solder joints are firm and reliable, strong anti-vibration ability, and low solder joint defect rate.

3.SMT soldered PCBA is electrically stable and low in energy consumption: short parts and wiring, fast transmission and less energy consumption, reducing electromagnetic and radio frequency interference, stable and reliable high frequency characteristics.

4. SMT is easy to realize automation, improve production efficiency, save materials, energy, equipment, manpower, time, and reduce costs by 30% to 50%.

1. Characteristics of THT plug-in technology

THT uses leaded components. Circuit connection wires and mounting holes are designed on the PCB. By inserting component leads into pre-drilled through holes on the PCB, temporary soldering such as wave soldering is used on the other side of the substrate. The technology performs welding to form reliable solder joints and establish long-term mechanical and electrical connections. Component bodies and solder joints are distributed on both sides of the substrate. With this method, because the components have leads, when the circuit is dense to a certain degree, the problem of reducing the size cannot be solved. At the same time, it is difficult to eliminate faults caused by the proximity of leads and interference caused by the length of the leads.DIP package is a part package in the THT plug-in process, also known as Dual In-line Package technology. It is the simplest packaging method. It refers to integrated circuit chips packaged in dual in-line form. Circuits use this package, and the number of pins does not exceed 100. The DIP packaged CPU chip has two rows of pins and needs to be inserted into a chip socket with a DIP structure.

On a conventional THT printed circuit board, components and solder joints are located on both sides of the board. On SMT circuit boards, solder joints and components are on the same side of the board. Therefore, in SMT printed circuit boards, through holes are only used to connect the wires PTH on both sides of the circuit board. The number of holes is much smaller and the diameter of the holes is much smaller. In this way, the assembly density of the circuit board can be greatly improved.

2. Characteristics of SMT surface assembly technology

1. SMT finished PCBA (Printed Circuit Board Assembly), with high assembly density, small size and light weight: the volume and weight of SMD components are only about 1/10 of those of traditional DIP through-hole plug-in components. After adopting SMT, the electronic products are reduced in size 40% ~ 60%, 60% ~ 80% lighter.2.SMT soldered PCBA has stable quality performance: solder joints are firm and reliable, strong anti-vibration ability, and low solder joint defect rate.

3.SMT soldered PCBA is electrically stable and low in energy consumption: short parts and wiring, fast transmission and less energy consumption, reducing electromagnetic and radio frequency interference, stable and reliable high frequency characteristics.

4. SMT is easy to realize automation, improve production efficiency, save materials, energy, equipment, manpower, time, and reduce costs by 30% to 50%.

More resources:

Do you have any questions about the above-mentioned? Contact us now, we will reply to you soon.

Is the article useful to you?

No

Yes(

10

)

10

451

1

Share to: