1. Definition | What is single-layer board, double-layer board and multilayer board

Single layer / Single-sided Printed Circuit Board

The single-panel wiring diagram is mainly screen printing, that is, a resist is printed on the copper surface. After etching, it is marked with a solder resist. Finally, the part guide holes and punching processing are completed. shape. In addition, some small and diverse products use a photoresist to form patterns.

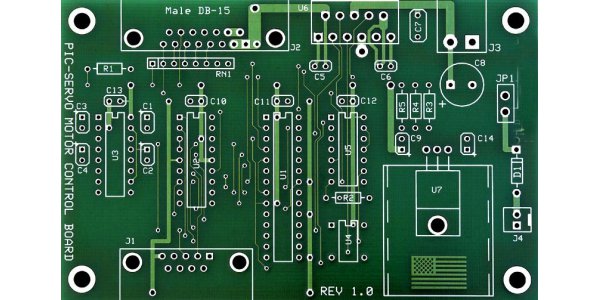

Double-layer Printed Circuit Board

What is a double-sided board means that there are copper foil circuits on the reverse side of the printed circuit board. Such a double-layer board is simpler than a single-panel wiring, and the wiring is more beautiful than a single-panel. Double-sided board is a very important kind of PCB in the circuit board. It is very useful. It is easy to see if a PCB is a double-sided board. I believe that my friends' understanding of single-sided board can be grasped. The double-sided board is an extension of the single-sided board, which means that the wiring of the single-sided board is not enough to turn to the reverse side. Another important feature of the double-sided board is that it has vias. To put it simply, it is a double-sided wiring, with lines on both sides!

One sentence is: a board with double-sided wiring is a double-sided board! Some friends will ask, for example, a board with double-sided wiring, but only one side has electronic parts. Is such a board double-sided or single-sided? The answer is obvious. Such a board is a double-sided board, and only the parts are mounted on the double-sided board!

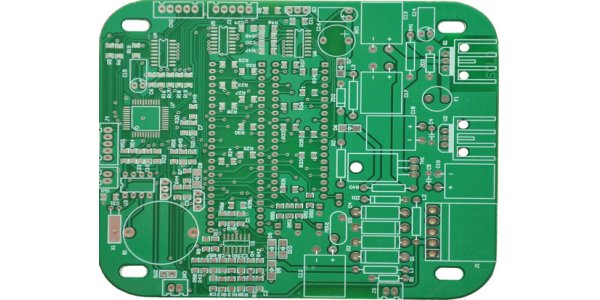

Multilayer Printed Circuit Board

The final multi-layer board refers to a printed board having three or more conductive pattern layers and an insulating material laminated therebetween, and the conductive patterns therebetween are interconnected as required. Multilayer circuit boards are the product of the development of electronic information technology in the direction of high speed, multifunction, large capacity, small size, thinness, and light weight.

How to see if a board is a multi-layer board, and the above has also told you what is a double-sided board, then a multi-layer board is more than two layers, such as four layers, six layers, eight layers, etc., everyone must remember There are no odd numbers of shelves, they are all multiples of two.

2.Single-Layer Board, Double-Layer Board, MultiLayer Board Use Difference

Single layer:

Copy and printer, radio equipment, calculator, LED panel, digital camera, radio and stereo equipment, washing machine, power adapter

Double layer

Consumer electronics, lighting systems, vending machines, amplifiers, automotive dashboards

Multilayer

Consumer electronics, computer electronics, automotive, industrial, medical equipment, telecommunications,

Military and defense, aerospace

3.Price Difference Between Single-Layer Board, Double-Layer Board And Multilayer Board

Single layer:Low cost

Double layer:Medium price

Multilayer:More expensive

The application area determines the cost of generating different types of circuit boards:

Single-layer circuit boards are mainly used in home electrical equipment, and the pursuit of rapid mass production. Single-layer printed circuit boards have the advantages of low cost and low technical difficulty, which is exactly the problem.

Double-layer circuit board: It is too simple to make up for the single-layer result, and it cannot solve the problem of complex circuit design. It is mainly for enterprises, followed by personal customers.

Multi-layer circuit board: It combines the problems that single-layer and double-layer boards can handle, and can be highly integrated, reduced, takes up less space, and solves more design problems. The most common in high-tech fields.

4.Difference in Manufacturing Process of Single-Layer Board, Double-Layer Board And Multilayer Board

Single-layer:fast, simple technology, general enterprise productionDouble-layered:Moderate

Multi-layered:high difficulty, cumbersome process, high-end enterprise production

The main differences in production processes are the difficulty in circuit design, the level and scale requirements for first-level production equipment.

Aipcba is a modern manufacturing enterprise integrating PCB production, smt assembly and electronic component sales, which solves various pain points of users.