Can SMD Components be Wave Soldered without a Carrier

Posted: May 14, 2022

By: Bonnie

SMD (Surface Mount Device) is different from SMT (Surface Mount Technology).

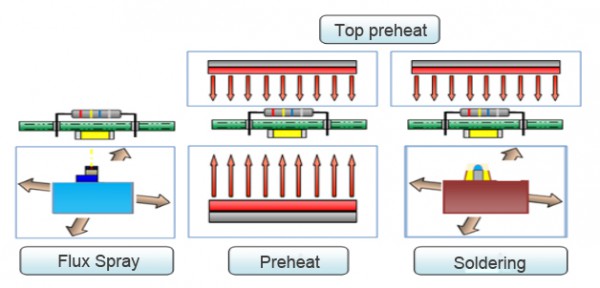

Wave soldering: The main soldering object is the electronic part of the traditional through hole (PTH) plug-in, because the plug-in part is placed above the PCB board, and the solder feet are exposed under the board through the through holes. The bottom of the circuit board slides over the solder surface of the wave soldering, so that the molten solder adheres to the solder pins of the parts and the through-hole pads of the circuit board to complete the soldering process.

So, can solder paste be used instead of red glue when SMD parts are wave soldered?

The answer is of course no. Because the solder paste and the solder composition in the wave soldering are almost the same, the melting temperature is almost the same. That is to say, the solder paste will melt when wave soldering. If there is no red glue, the SMD parts will fall directly into the solder furnace. .

Is it possible to print solder paste and red glue at the same time?

This dual process is feasible, and the purpose of doing so is to reduce the problems of over-wave soldering and air soldering. Because wave soldering is prone to occur Shadow Effect, the solder joints or parts under the shadow cannot easily contact the solder and cannot form a good solder. However, this requires an additional process, and the cost increases.

Secondly, the solder paste may remain under the red glue, causing an irregular bomb in quality, because when the solder paste is printed, sometimes the residual solder paste will stain the back near the opening of the Stencil. Put the red glue on the position where the solder paste remains, the solder paste will not be easily taken away by the solder liquid in the wave soldering furnace. The remaining solder may cause an electrical short circuit, or because of water after a period of use Gas and potential difference electromigration.

Generally, there must be no problem with small chip parts and SOTs above 0603. The other two rows of SOPs or SOICs with four rows of pins and QFP with four rows of pins can be used to a limited extent. For passive components below 0402, generally, ICs with bent legs inward (such as PLCC) or parts with solder legs under the body are not recommended to perform the wave soldering process, because it is easy to cause problems of self-short circuit or air soldering.

Therefore, the general wave soldering process board will focus on the first side of the circuit board (the side that does not wave wave solder) and the traditional plug-in parts are designed on the first side of the circuit board, while the second side is only placed for wave soldering SMD parts.

Is it impossible for QFN and BGA parts to be wave soldered on the second side (selective wave soldering)?

Sometimes due to circuit board design limitations, components such as QFN and BGA have to be designed on the second side of the circuit board. Such SMD parts that cannot be wave soldered cannot be designed on the second side of the circuit board. Generally, selective wave soldering is used, and the wave soldering carrier (template) is used to cover some parts that cannot be wave soldered, so that the tin wave will not contact those parts that cannot be wave soldered.

However, there are certain conditions for using selective wave soldering, such as the height limitation of parts, and the need to reserve space for the carrier when placing circuit board parts. The cost of the carrier is also a consideration.

Because of the prevalence of selective wave soldering, coupled with the increasingly thinner and smaller circuit boards, the use of over-vehicle carriers has gradually appeared. Therefore, not all wave soldering processes necessarily require furnace carriers.

Under what circumstances can a PCB pass a wave soldering furnace without a carrier?

3.1 PCB design requirements:

At least 5mm of PCB edge should be reserved for the use of wave soldering (gripper) and support when PCBA is placed magazine.

The thickness of the PCB should preferably be more than 1.6mm, so that warpage and overflow problems will not occur when passing through the furnace.

The gap distance of all pads is recommended to be more than 1.0mm to avoid shorting of the soldering points to each other.

3.2 Parts and layout requirements:

The type of SMD parts and the direction of SMD parts must meet the requirements of wave soldering. (In general, SMD parts need to be perpendicular to the direction of board travel)

The wave soldering surface of the circuit board only allows SMD parts, SOT, SOP, QFP, etc. of size above 0603 (inclusive), others such as BGA, PLCC, QFN, connector, transformer, 0402 (inclusive) and below Parts must not be placed on wavefront welds.

The plug-in parts must be all designed on the first side and the orientation of the plug-in parts must meet the requirements of wave soldering. (The pin must be parallel to the direction of the board)

The parts on the PCB must not be too heavy, to avoid the situation of bending the circuit board due to gravity.

3.3 Process requirements:

All SMD parts on the wave front soldering surface must be red glued to avoid falling into the wave soldering furnace.

Some solder pads (such as key contact lines and gold fingers) that cannot be tinned are not recommended to be designed on the wave solder contact surface (second side).

A few solder pads that can not be tin can be designed on the contact surface of the tin furnace, but must be pasted with wave front welding with high temperature tape that does not leave adhesive, and the tape should be removed after completion. Try to avoid this design to reduce labor.

Wave soldering: The main soldering object is the electronic part of the traditional through hole (PTH) plug-in, because the plug-in part is placed above the PCB board, and the solder feet are exposed under the board through the through holes. The bottom of the circuit board slides over the solder surface of the wave soldering, so that the molten solder adheres to the solder pins of the parts and the through-hole pads of the circuit board to complete the soldering process.

1. Can SMD parts also be wave soldered? Will the parts fall into the tin furnace?

If SMD parts want to go wave soldering, the red glue must be fixed to the circuit board at the bottom point of the part, and then the red glue is cured by oven (directly using the reflow oven). The heat resistance of this red glue must also be higher than the temperature of the soldering furnace, otherwise the SMD parts will melt and fall because they cannot withstand the high temperature when passing through the soldering furnace. Therefore, after the soldering furnace is used for a period of time, it is necessary to stop the furnace and pick up some parts sinking under the soldering furnace. Otherwise, after a long time, the parts in the tin furnace that are not adhered to the red glue will contaminate the solder and cause the problem of solder deterioration. In addition, not all SMD parts can be wave soldered.So, can solder paste be used instead of red glue when SMD parts are wave soldered?

The answer is of course no. Because the solder paste and the solder composition in the wave soldering are almost the same, the melting temperature is almost the same. That is to say, the solder paste will melt when wave soldering. If there is no red glue, the SMD parts will fall directly into the solder furnace. .

Is it possible to print solder paste and red glue at the same time?

This dual process is feasible, and the purpose of doing so is to reduce the problems of over-wave soldering and air soldering. Because wave soldering is prone to occur Shadow Effect, the solder joints or parts under the shadow cannot easily contact the solder and cannot form a good solder. However, this requires an additional process, and the cost increases.

Secondly, the solder paste may remain under the red glue, causing an irregular bomb in quality, because when the solder paste is printed, sometimes the residual solder paste will stain the back near the opening of the Stencil. Put the red glue on the position where the solder paste remains, the solder paste will not be easily taken away by the solder liquid in the wave soldering furnace. The remaining solder may cause an electrical short circuit, or because of water after a period of use Gas and potential difference electromigration.

2. Which SMD parts can be wave soldered?

SMD parts such as BGA, connector, transformer, QFN, etc. cannot be wave soldered because the solder cannot fully penetrate the bottom of the part (BGA and QFN) to form a solder joint, and some parts have Problems with short circuits or damaged parts (connectors and transformers).Generally, there must be no problem with small chip parts and SOTs above 0603. The other two rows of SOPs or SOICs with four rows of pins and QFP with four rows of pins can be used to a limited extent. For passive components below 0402, generally, ICs with bent legs inward (such as PLCC) or parts with solder legs under the body are not recommended to perform the wave soldering process, because it is easy to cause problems of self-short circuit or air soldering.

Therefore, the general wave soldering process board will focus on the first side of the circuit board (the side that does not wave wave solder) and the traditional plug-in parts are designed on the first side of the circuit board, while the second side is only placed for wave soldering SMD parts.

Is it impossible for QFN and BGA parts to be wave soldered on the second side (selective wave soldering)?

Sometimes due to circuit board design limitations, components such as QFN and BGA have to be designed on the second side of the circuit board. Such SMD parts that cannot be wave soldered cannot be designed on the second side of the circuit board. Generally, selective wave soldering is used, and the wave soldering carrier (template) is used to cover some parts that cannot be wave soldered, so that the tin wave will not contact those parts that cannot be wave soldered.

However, there are certain conditions for using selective wave soldering, such as the height limitation of parts, and the need to reserve space for the carrier when placing circuit board parts. The cost of the carrier is also a consideration.

3. Under what conditions can the PCBA board be directly wave soldered without a carrier?

In the early days, almost no carriers were used when assembling circuit boards. At that time, almost all PCBs were directly wave soldered without using any carriers, unless the circuit board could not bear too much load, such as the power board.Because of the prevalence of selective wave soldering, coupled with the increasingly thinner and smaller circuit boards, the use of over-vehicle carriers has gradually appeared. Therefore, not all wave soldering processes necessarily require furnace carriers.

Under what circumstances can a PCB pass a wave soldering furnace without a carrier?

3.1 PCB design requirements:

At least 5mm of PCB edge should be reserved for the use of wave soldering (gripper) and support when PCBA is placed magazine.

The thickness of the PCB should preferably be more than 1.6mm, so that warpage and overflow problems will not occur when passing through the furnace.

The gap distance of all pads is recommended to be more than 1.0mm to avoid shorting of the soldering points to each other.

3.2 Parts and layout requirements:

The type of SMD parts and the direction of SMD parts must meet the requirements of wave soldering. (In general, SMD parts need to be perpendicular to the direction of board travel)

The wave soldering surface of the circuit board only allows SMD parts, SOT, SOP, QFP, etc. of size above 0603 (inclusive), others such as BGA, PLCC, QFN, connector, transformer, 0402 (inclusive) and below Parts must not be placed on wavefront welds.

The plug-in parts must be all designed on the first side and the orientation of the plug-in parts must meet the requirements of wave soldering. (The pin must be parallel to the direction of the board)

The parts on the PCB must not be too heavy, to avoid the situation of bending the circuit board due to gravity.

3.3 Process requirements:

All SMD parts on the wave front soldering surface must be red glued to avoid falling into the wave soldering furnace.

Some solder pads (such as key contact lines and gold fingers) that cannot be tinned are not recommended to be designed on the wave solder contact surface (second side).

A few solder pads that can not be tin can be designed on the contact surface of the tin furnace, but must be pasted with wave front welding with high temperature tape that does not leave adhesive, and the tape should be removed after completion. Try to avoid this design to reduce labor.

All plug-in parts are recommended to use short-footed wave soldering to avoid short-circuit problems. It is recommended that the length of the foot of the part should not exceed 2.54mm.

More resources:

Do you have any questions about the above-mentioned? Contact us now, we will reply to you soon.

Is the article useful to you?

No

Yes(

11

)

11

989

1

Share to: