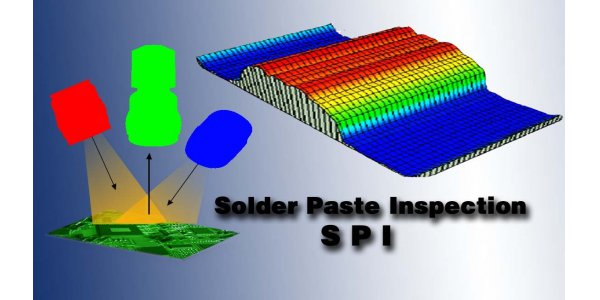

The application of solder paste is a key process in the SMT process, and metal stencil printing is the most common method currently used. Printing solder paste is the key process to ensure the quality of SMT. According to statistics, under the premise of PCB design specifications, components and printed board quality, 60%~70% of quality problems appear in the printing process.

1.The requirements for printing solder paste are as follows:

a. The amount of solder paste applied should be uniform and consistent, the solder paste pattern should be clear, the adjacent patterns should not be glued together, and the solder paste pattern should be consistent with the land pattern and should not be misaligned.b. Under normal circumstances, the amount of solder paste per unit area on the pad should be about 0.8mg/mm2, and for narrow-pitch components, it should be 0.5mg/mm2.

c. After solder paste printing, there should be no serious collapse, the edges are neat, and the surface of the substrate is not allowed to be contaminated by solder paste.

The physical and chemical properties of solder paste and process performance directly affect the quality of SMT soldering.

SMT Solder Paste Requirements and Performance

There are many types and specifications of solder paste. Even in the same manufacturer, there are differences in alloy composition, particle size, viscosity, etc. How to choose a solder paste suitable for your own products has a great impact on product quality and cost.

2. Correct use and storage of solder paste

The solder paste is a thixotropic fluid, the printing performance of the solder paste, the quality of the solder paste pattern and the viscosity of the solder paste, and the thixotropy relationship is extremely great, and the viscosity of the solder paste is in addition to the mass percentage content of the alloy, the alloy powder particle size, and the particle shape. In addition, it is also related to temperature. The change of ambient temperature will cause viscosity fluctuation. Therefore, it is best to control the ambient temperature at 23 °C ± 3 °C. Since the current solder paste printing is mostly carried out in the air, the ambient humidity will also be Influencing the quality of solder paste, generally requires relative humidity to be controlled at RH45%~70%. In addition, the working place of printing solder paste should be clean, dust-free and non-corrosive. At present, the assembly density is getting higher and higher, and the printing difficulty is getting bigger and bigger. The solder paste must be properly used and stored. The main requirements are as follows:1) Must be stored at 2~10 °C.

2) It is required to remove the solder paste from the refrigerator the day before (at least 4 hours in advance). After the solder paste reaches room temperature, the container lid can be opened to prevent condensation.

3) Stir the solder paste with a stainless steel mixing knife or an automatic mixer before use. Stir in one direction when mixing by hand. The machine or manual mixing time is 3~5min.

4) After adding the solder paste, cover the container.

5) No-clean solder paste can not use recycled solder paste. If the printing interval is more than 1 hour, the solder paste should be wiped off the template and the solder paste should be recycled to the container used in the day.

6) Reflow soldering within 4 hours after printing.

7) When no-clean solder paste is used, if the flux is not used, the solder joint should not be scrubbed with alcohol. However, if the flux is used during the repair, the residual flux that is not heated outside the solder joint must be scrubbed at any time because there is no The heated flux is corrosive.

8) The product to be cleaned should be cleaned on the same day after reflow soldering.

9) When printing solder paste and performing patch operations, it is required to take the edge of the PCB or bring gloves to prevent contamination of the PCB.