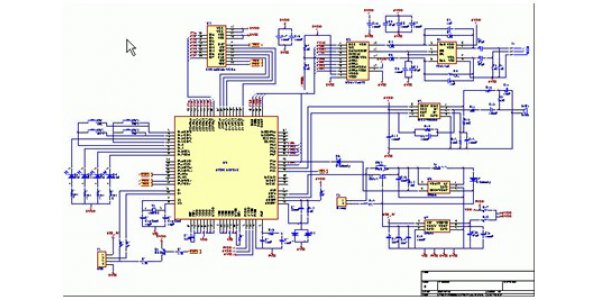

More commonly used in global are protel, protel 99se, protel DXP, Altium, these are the software developed by a company and constantly upgraded. The current version is Altium Designer 15 which is relatively simple, the design is more casual, but complex PCB software It's not very good. Cadence SPB is Cadence's software. The current version is Cadence SPB 16.5, ORCAD schematic design is an international standard. PCB design and simulation are very complete. It is more complicated to use than protel, mainly due to complicated requirements and settings. However, the design has been stipulated, so the design is more efficient, and it is obviously more powerful than protel. Mentor's BORDSTATIONG and EE, BOARDSTATION is only suitable for UNIX system, not designed for PC, so less people are used. The current MentorEE version is Mentor EE 7.9 and Cadence SPB belong to the same level of PCB design software, it has some places Inferior to cadence SPB, its strengths are pull wire and flying wire. EAGLE Layout This is the most widely used PCB design software in Europe. The PCB design software mentioned above is used a lot, and Cadence SPB and MentorEE are well-deserved kings. If it is a beginner to design PCB, Cadence SPB is better, it can give designers a good design habit, and can ensure good design quality.

1) Design skills

The design needs to be set at different points in different stages. In the layout stage, large grid points can be used for device layout. For large devices such as ICs and non-positioning connectors, you can choose a grid accuracy of 50-100 mils for layout. For passive small devices such as resistors, capacitors, and conductors, you can use 25 mil grids for layout. The accuracy of the large grid points is conducive to the alignment of the device and the aesthetics of the layout. There are six tips for selecting components when designing PCB.

Under normal circumstances, all components should be placed on the same surface of the circuit board. Only when the top layer components are too dense, can some limited height and small heat generation devices, such as chip resistors, chip capacitors, chip ICs Wait at the bottom. Under the premise of ensuring electrical performance, the components should be placed on the grid and arranged parallel or perpendicular to each other to be neat and beautiful. In general, the components are not allowed to overlap; the components should be arranged compactly, and the components should be evenly distributed on the entire layout, maintaining consistent density. The minimum distance between adjacent pad patterns of different components on the circuit board should be above 1MM. It is generally not less than 2MM away from the edge of the circuit board. The best shape of the circuit board is rectangular, and the aspect ratio is 3:2 or 4:3. When the circuit board surface size is greater than 200MM by 150MM, the mechanical strength that the circuit board can withstand should be considered. The circuit board size has design rules for planning and control.

3) Layout skills

In the layout design of the PCB, the units of the circuit board should be analyzed, and the layout design should be based on the function. When laying out all the components of the circuit, the position of each functional circuit unit should be arranged according to the flow of the circuit, so that the layout is convenient for signal circulation, and try to keep the signal in the same direction as possible. With the core components of each functional unit as the center, layout around him. The components should be evenly, integrally and compactly arranged on the PCB to minimize and shorten the leads and connections between the components. For circuits operating at high frequencies, the distribution parameters between components must be considered. The general circuit should arrange the components in parallel as much as possible, which is not only beautiful, but also easy to install and solder, and easy to mass produce.