If there is no impedance control, it will cause considerable signal reflection and signal distortion, leading to design failure. Common signals, such as PCI bus, PCI-E bus, USB, Ethernet, DDR memory and LVDS signal, need impedance control. Finally, impedance control needs to be realized through PCB design, and higher requirements for PCB technology are put forward. After communication with PCB Factory and combining with the use of EDA software, the impedance of wiring is controlled according to the requirements of signal integrity. The corresponding impedance value can be obtained by calculation for different wiring modes.

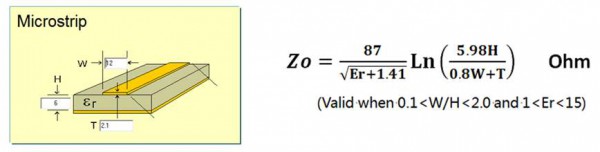

1)Micro-strip line

It is composed of a strip wire and the ground plane with a dielectric in the middle. If the dielectric constant, the width of the line, and the distance from the ground plane are controllable, the characteristic impedance of the dielectric is controllable, and the accuracy will be within ± 5%.

2) Stripline

A stripline is a copper strip placed in the middle of a dielectric between two conductive planes. If the thickness and width of the wire, the dielectric constant of the dielectric and the distance between the two grounding planes are controllable, the characteristic impedance of the line is also controllable, and the accuracy is within 10%.

In order to control the impedance of PCB well, we must understand the structure of PCB. In general, the multi-layer board is composed of core board and semi curing sheet. The core board is a kind of hard plate with specific thickness and two layers of copper, which is the basic material of printed circuit board. The so-called wetting layer formed by the semi cured sheet plays the role of bonding the core board. Although it has a certain initial thickness, its thickness will change during the pressing process.

Usually, the two outermost dielectric layers of multilayer board are the wetting layer, and a separate copper foil layer is used as the outer copper foil. The original thickness specifications of outer copper foil and inner copper foil are generally 0.5oz, 1oz and 2oz (1oz is about 35um or 1.4mil). However, after a series of surface treatment, the final thickness of outer copper foil will increase by about 1oz. The inner copper foil is the copper clad on both sides of the core plate. The final thickness of the inner copper foil is slightly different from the original thickness. However, due to etching, it can be reduced by several um.

The outermost layer of multilayer board is solder mask, which is often called "green oil". Of course, it can also be yellow or other colors. It is not easy to determine the thickness of solder mask accurately. The area without copper foil on the surface is slightly thicker than that with copper foil. However, due to the lack of thickness of copper foil, the copper foil is still more prominent. We can feel it when we touch the surface of printed circuit board with our fingers. When making PCB with a certain thickness, on the one hand, it is required to select the parameters of various materials reasonably, on the other hand, the final forming thickness of the semi cured wafer will be smaller than the initial thickness.

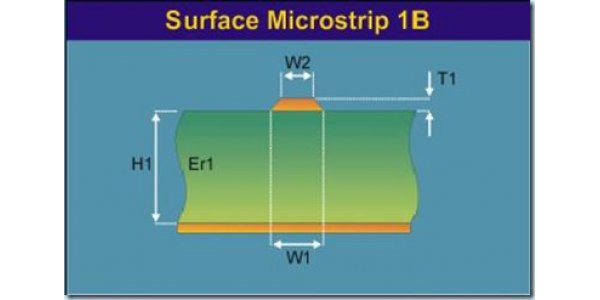

When we understand the structure of the multilayer plate and master the required parameters, we can calculate the impedance through EDA software. Allegro can be used to calculate, but here we recommend another tool, polar SI9000, which is a good tool for calculating characteristic impedance. Now many PCB factories are using this software.

Whether it is a differential line or a single ended line, when calculating the characteristic impedance of the inner layer signal, you will find that there is only a small difference between the calculation results of polar SI9000 and Allegro, which is related to the processing of some details, such as the shape of the cross section of the conductor. However, if it is to calculate the characteristic impedance of the surface signal, it is recommended to choose coated model, because this kind of model takes into account the existence of solder mask, so the results will be more accurate.