Resistance

When AC current flows through a conductor, the resistance is called impedance, which corresponds to Z, and the unit is Ω.

The resistance at this time is different from that of DC current. Besides resistance of resistance, there are resistance problems of inductive reactance (XL) and capacitive reactance (XC). In order to distinguish the resistance of direct current, the resistance encountered by alternating current is called impedance (z).

Impedance (z)

In recent years, with the improvement and application of IC integration, the signal transmission frequency and speed are getting higher and higher. Therefore, when the signal transmission (transmission) reaches a certain value, it will be affected by the PCB wire itself, resulting in serious distortion or complete loss of the transmission signal. This shows that the "thing" flowing through PCB wire is not the current, but the transmission of square wave signal or pulse in energy. You can calculate impedance during PCB design process.

Characteristic impedance control (Z0)

The resistance of the above "signal" transmission is also called "characteristic impedance", and the symbol is Z0. Therefore, it is not enough to solve the problems of "on", "off" and "short circuit" on PCB wire, but also to control the characteristic impedance of wire. In other words, the quality of transmission lines for high-speed transmission and high-frequency signal transmission is much stricter than that of transmission wires. It is no longer "open / short circuit" test pass, or notch, burr does not exceed 20% of the line width. It must be required to measure the characteristic impedance value, and the impedance should be controlled within the tolerance, otherwise, it is only scrapped and cannot be reworked.

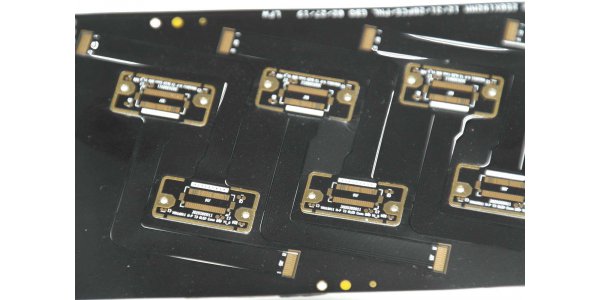

In the production of PCB circuit board, impedance processing is indispensable. Because PCB circuit board (board bottom) needs to consider the plug installation of electronic components, after the plug in consideration of conductivity and signal transmission performance and other factors, so the lower the impedance, the better. PCB circuit board in the production process has to go through copper deposition, electro tinning (or electroless plating, or hot spray tin), connector soldering process, and the materials used in these links must ensure the low resistivity, to ensure that the overall impedance of the circuit board is low, meet the product quality requirements, and can operate normally. The tin plating of PCB circuit board is the most easy problem in the production of the whole circuit board, and it is the key link that affects the impedance. The biggest defect of electroless tin coating is easy to change color (easy to oxidize or deliquescence), poor solder-ability, which will lead to the circuit board difficult to weld, high impedance, poor conductivity or instability of the whole board performance. There will be all kinds of signal transmission in the conductor of the circuit board factory. When the frequency must be increased in order to improve the transmission rate, if the circuit itself is different due to etching, stack thickness, wire width and other factors, the impedance value will change, the signal will be distorted and the performance of the circuit board will be reduced. Therefore, it is necessary to control the impedance value within a certain range. For the electronic industry, according to the industry survey, the most fatal weakness of electroless tin coating is easy to change color (ie. Easy to oxidize or deliquescence), poor solder-ability leads to difficult soldering, high impedance leads to poor conductivity or instability of the whole board performance, and easy to grow tin leads to PCB circuit short circuit, burn out or fire events.