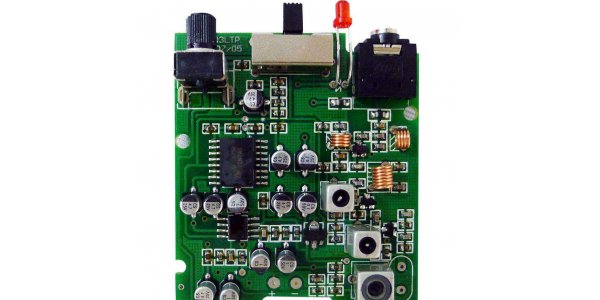

What is printed circuit board?

PCB, as a printed circuit board, is an important electronic component, the support body of electronic components and the carrier of electrical connection. Because it is made by electronic printing, it is called "printed" circuit board. There are three main types of PCB: single panel, single panel is on the most basic PCB, parts are concentrated on one side, and wires are concentrated on the other side (when there are patch components, the same side as the wire, and the plug-in device is on the other side). Double sided board, this kind of circuit board has wiring on both sides, but to use two sides of the wire, you must have a proper circuit connection between the two sides. Multi layer board, in order to increase the area of wiring, multi-layer board uses more single or double-sided wiring board.

PCB can be more and more widely used, because it has many unique advantages. For decades, PCB high-density can be developed with the improvement of integrated circuit integration and the progress of installation technology. Through a series of inspection, test and aging test, PCB can work reliably for a long time (service life, generally 20 years). For PCB performance requirements (electrical, physical, chemical, mechanical, etc.), PCB design can be realized through design standardization and standardization, which is short time and high efficiency. PCB under modern management, can carry out standardization, scale (quantity) and automation production, and ensure the consistency of product quality. And established a relatively complete test method, test standards, a variety of test equipment and instruments to detect and identify the PCB product qualification and service life. PCB products not only facilitate the standardized assembly of various components, but also can be automated, large-scale mass production. At the same time, PCB and various components can also be assembled to form larger parts, systems, and even the whole machine. Because PCB products and various components are designed and produced in a standardized way, these components are also standardized. See more comparison of advantages and disadvantages between different layers PCB.

What is breadboard?

Breadboard is an indispensable tool in electronic experiment. In short, breadboard is a kind of electronic experiment equipment. The surface of bread board is perforated plastic, and there are metal strips at the bottom. Electronic components can be inserted according to certain rules and can be used without welding. The internal connection of the upper and lower parts of the bread plate is different from that of the middle part.

Solder-less breadboard is a board that has no motherboard as a base, no welding power outlet, but can expand the single breadboard. It should be electrified before use. Connect the two poles of the power supply to the sockets on both sides of the bread board, and then you can plug in the components for experiment (disconnect the power supply in the process of inserting components). When there are more than 5 components or a group of jacks cannot be inserted, it is necessary to connect multiple sets of jacks with bread board connecting wire.

The single bread board is a bread board with motherboard as the base, and the power supply is connected with a special terminal, and even some can carry out high-voltage experiments with ground wire terminals. This kind of board is convenient to use. It is to connect the power supply directly to the terminal, and then insert the components for experiment (the power supply should be disconnected during the process of inserting components). When there are more than 5 components or a group of jacks cannot be plugged in, it is necessary to connect multiple sets of jacks with bread board connecting wire.

Combined bread board is a kind of board which combines many solder-less bread boards together. Generally, 2-4 solder-less breadboards are fixed on the motherboard, and then the power wires of each board are connected with copper foil in the motherboard. The professional combination bread board also specially designs the sub power control for different circuit units, so that each board can carry different voltage according to the user's needs. The use of combination breadboard is the same as that of single breadboard.

Comparison

1) Complexity: breadboard only needs wires and components to plug in, so the operation is complex, the circuit is chaotic, and it is easy to make mistakes. The PCB version is easy to operate, easy to mark and clear the circuit.

2) Connection mode: bread board is plug-in circuit, PCB is welding circuit, the former is easy to cause poor contact, the latter is relatively stable.

3) Application scope: bread board is suitable for less components, low signal interference requirements, small circuit current, temporary test circuit, relatively low cost; PCB board has multi-layer type, can almost realize the welding of all circuits, grading shielding signal is also easy to achieve, but requires professional software design and processing, the cost is high.

There is a time when you would use a breadboard over a PCB, and the other way around. According to what you are making and the stage you are at, which will help you decide when to use either a breadboard or a PCB. In general, breadboards can be used to test connections and circuits. So you can move the circuit without damaging the printed circuit board, because the circuit board is not permanent. However, with a minimum current capacity, you'd better be prepared before developing the actual board, because it's not a permanent board. As you know, printed circuit boards can be used in actual electronic devices. More importantly, you can develop a printed circuit board after testing the board to find the perfect design for your project. There is no doubt that PCB is a permanent device in electronic products, because it needs to be welded, so PCB board has been widely used in your electronic projects.