It is a kind of "thermal conductive organic ceramic circuit board with thermal conductivity of 9-20w /m.k was prepared under the condition of lower than 250℃ using thermal conductive ceramic powder and organic adhesive.

Ceramic PCB application industry:

Ceramic PCBS are actually made from electronic ceramic materials and can be made into various shapes. Among them, ceramic PCB has the most outstanding features of high temperature resistance, high electrical insulation performance, low dielectric constant, low dielectric loss, high thermal conductivity, good chemical stability, similar thermal expansion coefficient of components and other advantages. Ceramic PCB is produced by LAM technology using laser rapid activation metallization technology. Used in LED field, high power semiconductor module, semiconductor cooler, electronic heater, power control circuit, power hybrid circuit, intelligent power element, high frequency switching power supply, solid state relay, automotive electronics, communications, aerospace and military electronics.

Unlike traditional fr-4 (fiberglass), ceramic materials have good high frequency and electrical properties, as well as high thermal conductivity, chemical and thermal stability. Ideal packaging material for generating large scale integrated circuits and power electronics modules.

Main advantages:

1.Higher thermal conductivity;

2.More suitable thermal expansion coefficient;

3.a harder, lower resistance of metal film alumina ceramic circuit board;

4.The solderability of the substrate is good and the operating temperature is high;

5.Good insulation;

6.Low frequency loss;

7.High density assembly;

8.no organic components, resistant to cosmic rays, aerospace reliability, long service life;

9.the copper layer does not contain oxide layer, can be used for a long time in the reducing atmosphere.

Advantages of ceramic PCB:

1).With the development of high-power electronic products towards miniaturization and high-speed, the traditional substrate materials such as fr-4 and aluminum substrate are no longer suitable for high-power and high-power development. With the progress of science and technology, intelligent application of PCB industry. The traditional LTCC and DBC technologies are gradually replaced by DPC and LAM technologies. Laser technology represented by LAM technology is more in line with the development of high density interconnect and fineness of printed circuit board. Laser drilling is the front and main technology of PCB industry. The technology is efficient, fast, accurate and has high application value. RayMingceramic circuit boards are fabricated using laser rapid activation metallization technology. The bond between the metal layer and the ceramic is strong, has good electrical properties, and can be repeatedly welded. The thickness of the metal layer can be adjusted in the range of 1m -1mm to achieve L/S resolution. 20 m, can be directly implemented through the connection to provide customers with customized solutions.

2).Compared with conventional lasers, the output power of the transversely excited atmospheric CO2 laser is up to one hundred to one thousand times, and it is easy to manufacture. In the electromagnetic spectrum, radio frequencies range from 105 to 109Hz, and with the development of military and aerospace technology, secondary frequency launches. Medium and small power rf CO2 laser has excellent modulation performance, stable power and high operating reliability. Long life. UV solid YAG is widely used in plastics and metals in microelectronics industry. Although the process of CO2 laser drilling is relatively complex, the production effect of micro aperture is better than that of UV solid YAG, but CO2 laser has the advantages of high efficiency and high speed stamping, the market share of PCB laser microhole processing is still in the development stage, and there are not many enterprises can be put into production.

3).Laser microporous manufacturing is still in the development stage in China. Short pulse and peak power lasers are used to drill holes in PCB substrates to achieve high density energy, material removal and micropore formation. Ablation is divided into photothermal ablation and photochemical ablation. Photothermal ablation is the process of hole formation by rapidly absorbing high-energy laser from the substrate material. Photochemical ablation refers to the combination of specular energy in the ultraviolet region over 2eV electron volts and laser wavelength over 400nm. The manufacturing process can effectively destroy the long molecular chains of organic materials, forming smaller particles, which can quickly form micropores under the action of external forces.

4).Compared with the traditional stamping technology, the laser drilling technology has high precision, high speed, high efficiency, large scale punching, suitable for most soft and hard materials, no loss of tools, produce waste. Less materials, environmental protection, pollution-free advantages.

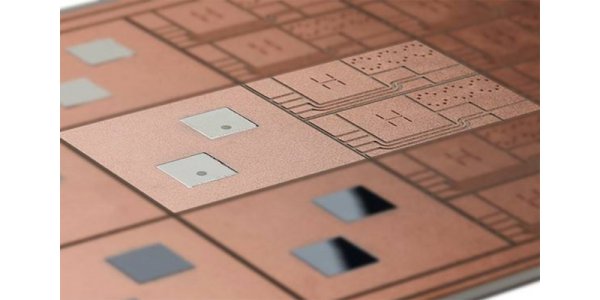

5).Ceramic PCB through laser drilling process, the bonding force between ceramics and metal is high, not falling off, foaming, and the effect of growth together, high surface roughness, roughness ratio 0.1 micron to 0.3 micron, laser strike hole diameter from 0.15 mm to 0.5 mm, even 0.06 mm.

Ceramic PCB manufacturing - etching:

1).The circuit pattern is pre-coated with a lead-tin corrosion inhibitor on the copper foil remaining on the outer layer of the PCB, and then chemically etched away the copper from the unprotected non-conducting part to form the circuit.

2).According to different process methods, etching is divided into inner layer etching and outer layer etching. The outer etching is alkaline etching and tin lead is used as corrosion inhibitor.

The fundamentals of etching reactions:

1.Acidic copper chloride alkalization:

1).Development: the part of the dry film that has not been irradiated by ultraviolet light is dissolved by weakly alkaline sodium carbonate, and the irradiated part remains.

2).Etching: the copper surface exposed by dissolving a dry or wet film is dissolved and etched by an acidic copper chloride etching solution in accordance with a certain proportion of the solution.

3).Fade film: the protective film on the production line dissolves at a certain rate of temperature and speed.

4).The acidic copper chloride catalyst has the characteristics of easy to control the etching speed, high etching efficiency, good quality and easy to recover the etching solution.

2.Alkaline etching:

The alkaline etching:

1).Fade film: remove film from film surface with meringue to expose raw copper.

2).Etching: an unwanted substrate is etched with an etching agent to remove the copper, leaving a thickened line. Where, auxiliary equipment will be used. The promoter is used to promote oxidation reaction and prevent cuprous ion precipitation. Insect repellents are used to reduce side erosion; Inhibitors are used to inhibit ammonia dispersion, copper precipitation, and accelerate copper oxidation.

3).New emulsion: the use of a water without copper ions ammonia, remove residues with ammonium chloride solution on the plate of liquid.

4).Full hole: this procedure is only applicable to gold dipping process. In order to prevent gold ions from sinking in the gold sinking process, it is necessary to remove the excess palladium ions in the plating hole.

5).Tin stripping: tin - lead layer is removed using nitric acid solution.