Flexible PCB is a printed circuit made of flexible insulating substrate, which has many advantages that hard PCB does not have:

1). it can bend, wind and fold freely, can be arranged arbitrarily according to the spatial layout requirements, and can move and expand arbitrarily in the three-dimensional space, so as to achieve the integration of component assembly and wire connection;2). the use of FPC can greatly reduce the volume and weight of electronic products, suitable for the development of electronic products to the direction of high density, miniaturization, high reliability. Therefore, FPC has been widely used in aerospace, military, mobile communication, laptop, computer peripherals, PDA, digital camera and other fields or products.

3). FPC also has the advantages of good heat dissipation and weldability, easy installation and connection, and low comprehensive cost. The design of combining soft and hard also makes up for the slight shortage of flexible substrates in the bearing capacity of components to some extent.

Disadvantages of flexible PCB (FPC) :

1).high one-time initial cost: since the flexible PCB is designed and manufactured for special applications, the initial circuit design, wiring and photographic substrate require higher costs. Unless there is a special need to apply soft PCB, usually a small number of applications, it is best not to use;

2).it is difficult to change and repair the soft PCB: once the soft PCB is made, it must be changed from the bottom drawing or the light drawing program, so it is not easy to change. Its surface is covered with a protective film, which should be removed before repair and restored after repair.

3).size limitation: the soft PCB is usually manufactured by intermittent process under the condition that it is not widely used, so it is limited by the size of production equipment and cannot be made very long and wide;

4).improper operation is easy to damage: improper operation of the connecting personnel is easy to cause damage to the soft circuit, and its tin welding and rework need to be operated by trained personnel.

Flexible PCB features:

1).Short: short assembly hours:

All lines are configured to complete, eliminating the redundant wiring connection work;

2).Small: smaller than PCB:

Can effectively reduce the volume of the product, increase the convenience of carrying;

3).Light: lighter in weight than PCB:

Can reduce the weight of the final product;

4).Thinner: thinner than PCB:

Can improve the flexibility, strengthen the limited space for three - dimensional assembly.

Flexible PCB classification:

1). Single-sided flexible PCB:

Lowest cost. When the electrical performance requirements are not high, and can be single-sided wiring, should choose a single-sided flexible plate. This most common form has found commercial applications, such as jet cartridges for printers and memory for computers. The single-sided flexible plate has a layer of conductive graph etched by chemical etching, and the conductive graph layer on the flexible insulating substrate is calendered copper foil. Insulation substrates used for flexible assembly may be polyimide (Kapton), polyethylene terephthalate (PET), aromatic amide fiber paper (Nomex), and polyvinyl chloride (PVC).

Single-sided flexible PCB with double channels: some single-sided flexible PCB have a double-channel design that allows you to access conductive material from both sides of the circuit. This design feature requires a flexible PCB and dedicated layer to provide access to a single copper layer through the polyimide layer of the substrate.

As a connecting device, the main advantage is that compared with the traditional cable and rigid circuit board, flexible circuits include: reduce the wrong wiring, eliminate mechanical connectors, unparalleled design flexibility, higher working temperature range of circuit density and stronger and stronger signal quality, improve the reliability and the impedance control, reduce the size and weight.

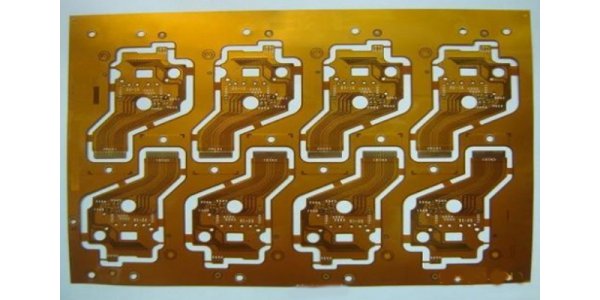

2). Double-sided flexible PCB:

The double-sided flexible plate is a conductive pattern etched on two sides of the substrate. Metallized holes connect the two sides of the insulating material to form a conductive path to meet the design and use of flexural function. The covering film can protect the single and double sides of the wire and indicate the placement of the element.

There is a big difference between the manufacturing method of the flexible double-sided PCB board and the flexible single-sided PCB board. The following is the general manufacturing process of the double-sided flexible PCB board with metallized hole and reinforced plate:

Opening one drill through hole one hole metallization one copper foil surface cleaning one anticorrosive coating one conductive pattern forming one etching, one anticorrosive stripping one coating film processing one terminal surface electroplating one shape and one hole processing one inspection one packaging of one reinforcing plate.

3). Multilayer flexible PCB:

Multilayer flexible board is to layer three or more layers of single-sided flexible circuit board or double-sided flexible circuit board together, through drilling, electroplating to form a metal hole, formed a conductive path between different layers. In this way, no complicated welding process is needed. Although the number of conductive layers designed for this flexible type can be unlimited, the interaction of assembly size, number of layers, and flexibility should be taken into account when designing the layout to ensure assembly convenience.

The invention relates to a multi-layer flexible circuit board, which comprises the uppermost outer conductor layer and the lowermost outer conductor layer. At the same time, the uppermost outer conductor layer and the lowermost outer conductor layer are in contact with and overlap with the pure rubber layer, and the outer conductor layer forms a multi-layer structure through the pure rubber layer and the conductor layer, which is characterized by: the glue-free zone formed by windowing of the pure rubber layer is from the inner layer to the outer layer in the order from large to small.

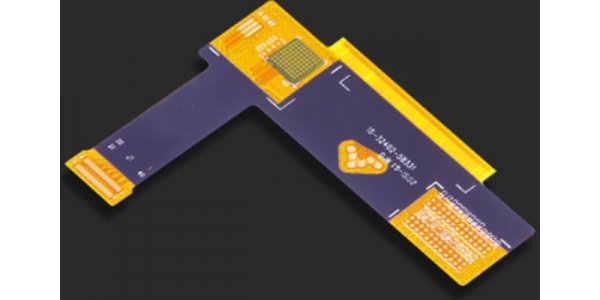

4). Rigid - flexible combination:

The traditional rigid flexure plate is composed of selective formation compression of rigid and flexible substrates. The structure is compact, forming conductive connection with metallized holes. Considering the reliability and price factors, the factory should try to maintain as few layers as possible.

High Density Interconnection (HDI) High Density combined printed circuit board (HDI) is a high-end printed circuit board product that aims to meet the growing demand of electronic products toward miniaturization, high-frequency high-speed, and multiactivity. HDI rigid-flexible joint board combines the advantages of popular HDI board and rigid-flexible joint board, and promotes the development of high integration and high intelligence in the design and production of electronic system. It has been widely used in high-end electronic products such as aerospace skills, medical equipment and cost.