1).PCB production cost is related to the actual area. When the length and width of PCB are within 5CM, the cost of 4-layer PCB is almost twice that of 2-layer PCB. When the length and width are between 5-10cm, the cost of 4 layers is about 4 times of that of 2 layers.

2).Through the hole 0.5/0.8, some PCB board manufacturers can't do, if the board sub-space is limited can only do so small, it is necessary to confirm with the board factory in advance, when the furnace is too large, tin is easy to run to the board.

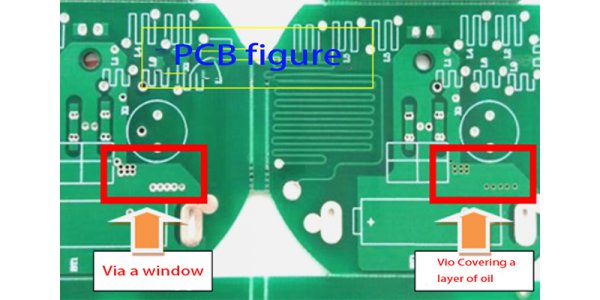

3).Through the hole is actually the same as the welding pad, but not the welding elements. However, due to the production process (special case is another), the size of the through hole welding pad should be more than 0.5MM larger than the through hole. And choose standard pad size first.

Through hole size of PCB:

The PCB process control block is a static description of the process, which is composed of PCB, the relevant program segment and the data structure set that the program segment operates on.

In Unix or unix-like systems, a process is composed of a process control block, the program that the process executes, the data that the process USES when it executes, and the workspace that the process runs in. The process control block is the most important part.

Process control block is used to describe the current state of the process, its own characteristics of the data structure, is the most critical part of the process, which contains the description of the process information and control information, is the process of centralized characteristics of the reflection, is the operating system to identify and control the process.

4 layer PCB cost estimation example:

A simple 2 x 4 inch 4 layer circuit board. We assume that it is suitable for household electronics - so no special materials are required. There is usually a first installation fee, which is required for the engineer to work and adjust the Gerber files and set up the printer. Installation costs rarely exceed $200, despite the work involved. For complex layouts, it's still higher.

The unit price depends on the materials used, the need for drilling and access, and other factors. Like book publishing and other printing jobs, the larger the order, the lower the price. A test batch of 100 boards can cost more than $2 per unit. For orders over 10,000, your unit price is close to one dollar. The high temperature material usually doubles the unit price, but when you need it, you just use it. Savings in material costs may affect the success of the product.

Control PCB cost requirements:

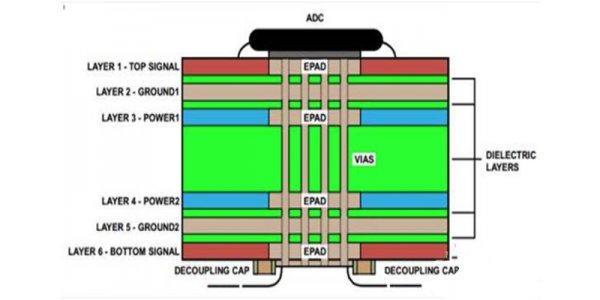

1).Number of PCB layers:

In general, the more layers of PCB, the more expensive it is for the same area. The design engineer should use as few layers as possible to complete the PCB design while ensuring the quality of the design signal.

2).PCB size:

With a certain number of layers, the smaller the PCB, the lower the price. If the design engineer can reduce the size of PCB in PCB design without affecting the electrical performance, he can reasonably reduce the size and reduce the cost.

3). Manufacturing difficulty:

The main parameters affecting PCB manufacturing include minimum line width, minimum line spacing, minimum drilling, etc. If these parameters are set too small or the process capacity has reached the minimum limit of PCB factory, the yield of PCB will be lower and the production and manufacturing cost will increase. So in the process of PCB design, try to avoid challenging the limit of the factory, set 20 reasonable line width and line spacing, drilling, etc. In the same way, through hole can complete the design, try not to use HDI blind hole, because the processing technology of blind hole is much more difficult than through hole, which will increase the production cost of PCB.

4).PCB material:

PCB board classification of many, common paper - based printed circuit board, epoxy glass fiber cloth printed circuit board rice composite substrate printed circuit board, special substrate printed circuit board metal substrate. There is a big gap between different materials processing, and some special materials processing cycle will be longer, so try to choose in the design can meet the design requirements, and more common parity materials, such as RF4 materials.

4-layer PCB quotation contains factors:

1).The different production processes used lead to the diversity of prices:

Different production processes will result in different costs. Such as gilt plate and spray tin plate, the appearance of the production of gongs (milling) plate and (punch) plate, the use of silk screen line and dry film line will form different costs, resulting in the price of diversity.

2).Price diversity due to different difficulty:

Even if the material is the same, the process is the same, but the difficulty of the 4-layer PCB itself is different will cause different costs. If there are 1000 holes in both circuit boards, the hole size of one board is larger than 0.6mm and that of the other board is smaller than 0.6mm, different drilling costs will be generated. For example, two kinds of circuit boards are the same, but the line width and line spacing are different, one is more than 0.2mm, the other is less than 0.2mm, will also cause different production costs, because the difficult board scrap rate is higher, the cost is bound to increase, thus resulting in price diversity.

3).Price diversity caused by different manufacturers:

Even if the same product, but because of different process equipment, technical level, also can form different cost, nowadays a lot of manufacturers like gold plated board production, because the process is simple, low cost, but also a part of the factory production of gold plated board, scrapping the rise, cause cost increase, so they prefer to produce tin plate, so their tin plate quotation is lower than gold plated board instead.

4).Price difference caused by different payment methods:

At present, the PCB board factory will adjust the PCB price according to the different payment methods, ranging from 5% to 10%, thus causing the price difference.