What is Flexible PCB?

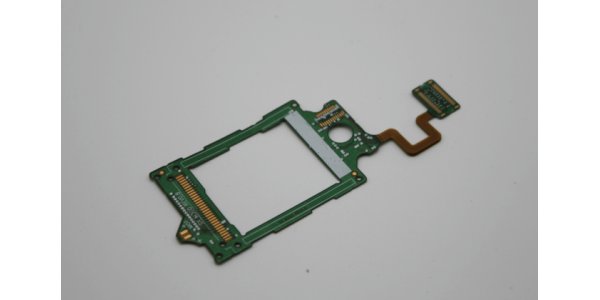

Flexible Printed Circuit is a conductive circuit pattern made by photo-imaging pattern transfer and etching process on the surface of a flexible substrate. The surface layer and inner layer of double-sided and multi-layer circuit boards are electrically connected to the inner and outer layers through metallized holes, and the surface of the circuit pattern is protected and insulated by PI and an adhesive layer.

FPC has the advantages of high wiring density, light weight, thin thickness, less restrictions on wiring space, and high flexibility. FPC is fully in line with the development trend of electronic products being light, thin and short, and is an effective solution to meet the requirements of miniaturization and mobility of electronic products.

FPC can be freely bent, wound, and folded, and can withstand millions of times of dynamic bending without damaging the wires. It can be arbitrarily arranged according to the spatial layout requirements, and can be moved and stretched arbitrarily in three-dimensional space, so as to achieve component assembly and wire connection. integration effect.

FPC can greatly reduce the volume and weight of electronic products, and is suitable for the development of electronic products in the direction of high density, miniaturization and high reliability. Therefore, it is widely used in PC and peripheral products, automotive electronics, medical equipment, communication products and consumer electronics products.

Flexible PCB in AiPCBA

The Flexible PCB we produce in AiPCBA are Single-sided, double-sided, multi-layer FPC, and rigid-flex boardsAiPCBA is a PCB and PCBA manufacturer that can provide one-stop PCB production services, aiming to create a PCB manufacturer with outstanding quality and cost-effectiveness. AiPCBA relies on its 7 years of experience in the electronic processing industry to strictly control the management of circuit board factories, optimize process capabilities, and improve internal and external sales and service levels. We stand out in the competition of PCB manufacturers and support through-hole PCB (Through-Hole PCB), flexible circuit board (FPC), etc. The PCB manufacturing quality and delivery time have won the trust of many customers at home and abroad in the market. Learn more about AiPCBA’s Turnkey PCB manufacturing.

Features of Flexible Circuit Boards

(1)The assembly time is short, and all the lines are configured, eliminating the need for the connection of redundant cables.

(2)The volume is smaller than PCB ( Rigid PCB), which can effectively reduce the product volume and increase the convenience of carrying.

(3)The weight is lighter than PCB ( Rigid PCB ), which can reduce the weight of the final product.

(4)Thinner than PCB ( Rigid PCB), it can improve the softness and strengthen the assembly of three-dimensional space in a limited space.

Advantages of Flexible Circuit Boards

A flexible printed circuit board is a printed circuit made of a flexible insulating substrate, which has many advantages that rigid printed circuit boards do not have.(1)The flexible circuit board can be freely bent, wound, and folded, and can be arbitrarily arranged according to the spatial layout requirements, and can be moved and stretched arbitrarily in three-dimensional space, so as to achieve the integration of component assembly and wire connection.

(2)It can greatly reduce the volume and weight of electronic products, and is suitable for the development of electronic products in the direction of high density, miniaturization and high reliability. Therefore, FPC has been widely used in aerospace, military, mobile communications, laptop computers, computer peripherals, PDA, digital cameras and other fields or products.

(3)FPC also has the advantages of good heat dissipation and solderability, easy assembly and connection, and low comprehensive cost. The design of soft and hard combination also makes up for the slight deficiency of the flexible substrate in the component carrying capacity to a certain extent.

The Main Materials of FPC

(1)Base material: The material is polyimide, which is a high temperature resistant and high strength polymer material. It can withstand a temperature of 400 degrees Celsius for 10 seconds and has a tensile strength of 15,000-30,000PSI. The 25μm thick substrate is the cheapest and most widely used. If the circuit board needs to be harder, a 50μm substrate should be used. Conversely, if the circuit board needs to be softer, a 13μm substrate is used.(2)Transparent adhesive for the substrate: divided into epoxy resin and polyethylene, both of which are thermosetting adhesives. The strength of polyethylene is relatively low. If you want the circuit board to be softer, choose polyethylene. The thicker the substrate and the clear glue on it, the stiffer the board. If the circuit board has a relatively large bending area, a thinner substrate and transparent adhesive should be used to reduce the stress on the surface of the copper foil, so that the chance of micro-cracks in the copper foil is relatively small. Of course, for such areas, single-layer boards should be used wherever possible.

(3)Copper foil: divided into rolled copper and electrolytic copper. Rolled copper has high strength and is resistant to bending, but it is more expensive. Electrolytic copper is much cheaper, but has poor strength and is easy to break. It is generally used in occasions where it is rarely bent. The choice of copper foil thickness depends on the minimum lead width and minimum spacing. The thinner the copper foil, the smaller the minimum width and spacing achievable. When choosing rolled copper, pay attention to the rolling direction of the copper foil. The rolling direction of the copper foil should be consistent with the main bending direction of the circuit board.

(4)Protective film and its transparent glue: 25μm protective film will make the circuit board harder, but the price is cheaper. For circuit boards with relatively large bending, it is best to use a 13μm protective film. Transparent glue is also divided into epoxy resin and polyethylene, and the circuit board using epoxy resin is relatively hard. When the hot pressing is completed, some transparent glue will be extruded from the edge of the protective film. If the size of the pad is larger than the size of the opening of the protective film, the extruded glue will reduce the size of the pad and cause its edges to be irregular. At this time, the transparent glue with a thickness of 13 μm should be used as much as possible.

PCB manufacturing and PCB Assembly in AiPCBA

AiPCBA has over 7 years of knowledge and combined experience in rendering high tech PCB assembly service, PCB manufacturing service and different PCB assembly technologies like Through-hole (THT) and Surface Mount (SMT). Mainly, we work with three types of printed circuit boards including Rigid PCB, Flexible PCB and metal core PCB.

We have customers from different industries in terms of cost-effectiveness, quality, delivery and any other requirements. From PCB layout to PCB prototyping, mass manufacturing, and then PCB assembly, electronic box assembly services, our printed circuit boards are widely used in robotics, medical, automotive, communications, industrial and consumer electronics products.

All PCBs in AiPCBA are produced based on UL and ISO certification standards. All our normal specification PCBs are strictly obeying to IPC-A-6011/6012 Class 2 latest version and IPC-A-600 Class 2 latest version.

Learn more about AiPCBA’s Turnkey PCB Assembly.