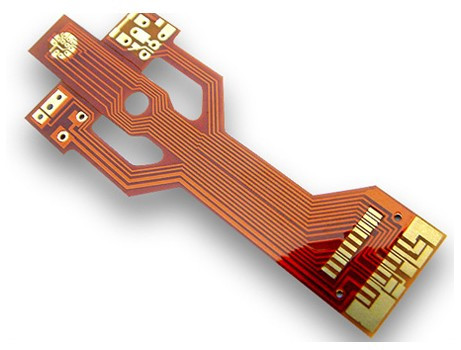

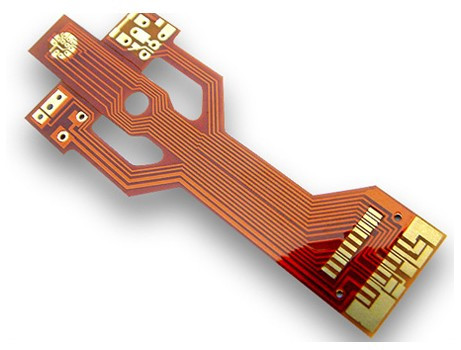

Flexible PCB (FPC)

PCBs are used in all electronic products and leads the market trend of PCBs. Alone with the development of high-end, miniaturized electronic products such as mobile phones, notebook computers and PDAs, the demand for flexible PCBs (FPC) is keep increasing. So PCB manufacturers are accelerating the development of thinner, lighter and denser FPCs.

A. Single Layer FPC

It has a layer of conductive pattern produced by chemical etching, and the layer of conductive pattern on the flexible insulating substrate surface is calendered copper foil. Insulation substrates can be polyimide, polyethylene terephthalate, aromatic amide fiber ester and polyvinyl chloride. Single-layer FPC can be divided into the following four sub-categories:

1. One-sided connection without overburdenThe conductor pattern is on the insulating base material, and there is no overlay on the surface of the conductor. Its interconnection is realized by tin welding, fusion welding or pressure welding. It is often used in early telephones.

2. One-sided connection with overlayCompared with the former, only one layer of overburden is added to the surface of the conductor. When covering, the pad should be exposed. Simply, it can not be covered in the end area. It is the most widely used one-sided soft PCB in automotive and electronic instruments.

3. Double-sided connection without overburden

Connecting disc interface can be connected on both front and back of the conductor. A path hole is opened on the insulating base material at the welding pad. The path hole can be made by punching, etching or other mechanical methods at the required position of the insulating base material.

4. Double-sided connection with overlay

A. Different from the former, there is a layer of covering layer on the surface, and the covering layer has access holes, which allow both sides to be terminated, and still maintain the covering layer, which is made of two layers of insulation material and one layer of metal conductor.

B. Double-sided FPC

Two-sided FPC has an etched conductive pattern on both sides of the insulating base film, which increases the wiring density per unit area. Metallized holes connect the graphics on both sides of the insulating material to form conductive paths to meet the flexibility of the design and use functions. The covering film can protect the single and double-sided conductors and indicate the location of the components. According to the requirements, metallized holes and coatings are optional, and this type of FPC is rarely used.

C. Multilayer FPC

Multilayer FPC is to laminate three or more layers of one-sided or two-sided flexible circuits together, through drilling L, electroplating to form metallized holes, forming conductive paths between different layers. In this way, complex welding process is not needed. Multilayer circuits have huge functional differences in higher reliability, better heat conductivity and more convenient assembly performance.