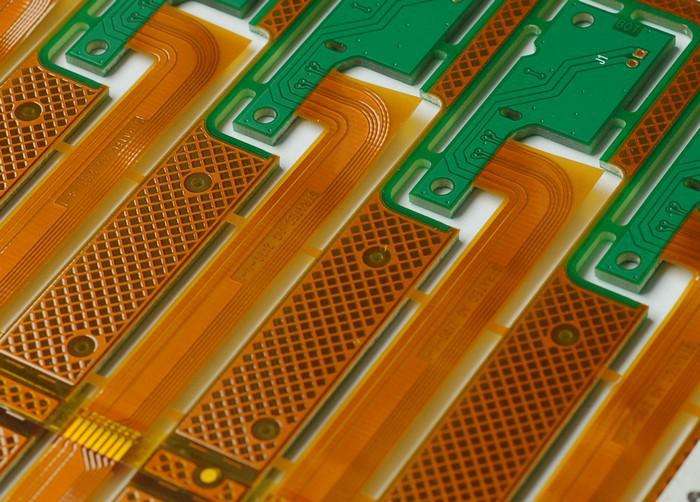

Rigid-flex PCB

As the name implies, the combination of rigid and flexible boards means that there are both rigid PCBs and flexible PCBs. Combining the advantages of the two boards, the space can be reduced as much as possible to achieve maximum utility. Meanwhile, the combination of rigid and flexible PCBs has both advantages and disadvantages.

Manufacturing process

Because the rigid-flex board is a combination of FPC and PCB, the production of the rigid-flex board should have both FPC production equipment and PCB production equipment. First, the electronic engineer draws the circuit and shape of the flexible bonding board according to the demand, and then sends it to the factory that can produce the flexible and rigid bonding board. After the CAM engineer processes and plans the relevant documents, then arranges the FPC production line production station FPC and PCB production lines are required to produce PCB. After these two flexible boards and hard boards come out, according to the planning requirements of electronic engineers, FPC and PCB are seamlessly pressed by a pressing machine, and then go through a series of details. It became a hard and soft board. It is a very important part, because the hard and soft combination board is difficult and has many details. Before shipment, it is generally necessary to carry out a full inspection, because its value is relatively high, so as not to cause the supply and demand sides to cause related losses of interest.

The advantages of rigid-flex PCB are as follows:

1. Shortening the distance and increasing the speed of signal transmission can effectively improve the reliability.

Traditionally, the signal transmission through the connector is circuit board connector flex PCB connector circuit board, whereas the signal transmission through the rigid-flex PCB is reduced to circuit board soft board circuit board. The distance of signal transmission is shorter, and the problem of signal transmission attenuation between different media is also reduced. Generally, the circuit on the circuit board is made of copper, and the contact terminals of the connector are gold-plated, the solder pins are plated with tin, and solder paste is used to solder the circuit board. The signal transmission between different media is inevitable. Some attenuation.The transmission of signals between different media will inevitably be somewhat attenuated. If use the rigid-flex PCB instead, these media will become less and the ability of signal transmission can also be achieved. Relative improvement will help to improve the reliability of some products with high demand for signal accuracy.

2. Simplify product assembly and save assembly time.

The use of rigid-flex PCBs can reduce the working hours of SMT parts, because the number of connectors is reduced. It also reduces the assembly time of the whole unit, because the assembly action of inserting the flex PCB into the connector is omitted, or the process of HotBar is omitted. It also reduces the cost of parts management and inventory, because BOM tables are reduced, so the management is reduced.

3. Can effectively save the space on the circuit board and save the process of using connectors or HotBar.

Because the rigid-flex PCBs have been combined, the space needed to use connectors or HotBar processes can be saved. For some PCBs with high-density requirements, it is more important to save space to fit.

The biggest disadvantage of rigid-flex PCB is the price. The price of rigid-flex PCB is more expensive than that of rigid PCB and flex PCB alone. However, if the price of connector or HotBar is deducted, the price of rigid-flex PCB may tend to be the same. Specifically, we need to look at the documents and then calculate carefully before we know. There are many production processes of rigid-flex PCBs, which are difficult to produce, and the quality is hard to control. The rigid-flex PCB also require many materials and cost. Therefore, the price of rigid-flex PCB is more expensive and the production cycle is longer. Another disadvantage is that SMT parts and ovens may need to use pallets to support the flex part, which will increase the cost of SMT.