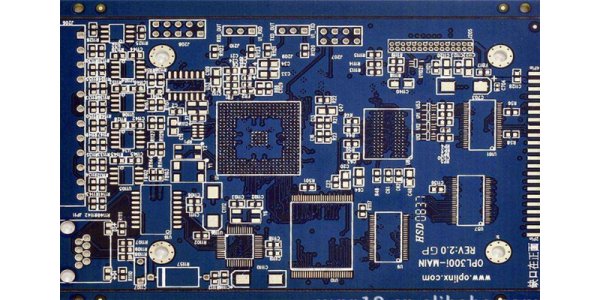

1.What is PCB:

PCB:It is an important electronic component, the support body of electronic components, and the carrier of electrical connection of electronic components.

2.PCB baidu various base plate introduction:

PCB various substrate is introduced, divided into: 94HB, fire board (94VO, FR-1, FR-2), semi-fiberglass (22F, CEM-1, CEM-3), all-fiberglass (FR-4).FR - 1 point:

1). Halogen-free plate, conducive to environmental protection

2). High resistance to electric leakage trace index (above 600 volts, special requirements are required)

3). The suitable punching temperature is 40 - 70℃

4). Bow curvature and twist rate are small and stable

1). Low cost and wide application

2). High quality moisture and heat resistance

3). Suitable for punching temperature of 40-70℃

4). Bow curvature and twist rate are small and stable

5). Superior dimensional stability

1). The electrical performance is similar to that of FR-4, the processing technology is the same as that of FR-4, and the wear rate of drill nozzle is smaller than that of fr-4

2). Multi-level resistance to electric leakage trace (CTI 175V, CTI300V, CTI 600V)

3). Comply with the specification requirements of IPC-4101A

1). No antimony and red phosphorus, no residual toxic components when burning

Antimony and red phosphor free, Absence of highly toxic dioxins in burning exhaust gas

2).The sheet material is Harder than KB-6160

3.Paper clad panel:

KB-3152/FR-1It is an environmentally friendly halogen-free product developed for environmental protection,antimony-free paper-based phenolic copper laminate can avoid the toxic substances produced when the burning plate contains halogen and antimony.

KB-3151S/FR-1:

It is designed to use high density automatic plug-ins,paper based phenolic resin copper PCB developed for the needs of precision circuit board such as surface adhesion technology of chip parts.excellent resistance to silver migration and electrical properties in wet environment.

KB-3150/KB-3151:

It is a new paper-based phenolic resin copper area laminate developed to meet the requirements of high-density automatic plug-in, chip surface adhesion technology and other precision circuit boards. It can have high leakage index (above 600V) and is suitable for low temperature punching operation.

KB-3150/FR-1:

It is a paper-based phenolic resin insulation laminate developed for precision components such as switch face box (such as piano key switch, push switch). It has excellent flame resistance and dimensional stability, and is suitable for low temperature punching operation.

KB-2151/FR-2:

It is a paper-based phenolic resin copper area laminate developed to meet the requirements of high-density automatic plug-in, wafer surface adhesion technology and other precision circuit boards.

KB-2150G/2150GC/FR-2:

It is an environment-friendly paper-based phenolic resin copper area laminate without halogen and antimony developed for environmental protection, which can avoid toxic substances and gases produced when the combustion plate contains halogen and antimony. It not only maintains the good performance of FR-2, but also has excellent resistance to humidity and heat.

KB-150/1150/150D Unclad (ANSI:XPC):

It is a paper-based phenolic resin insulation laminate developed for the demand of precision components for mechanical transmission. It has good resistance to humidity and heat, and is suitable for low temperature punching operation.

KB-1150/KB-1151 ANSI XPC:

It is a paper-based phenolic resin copper laminate with good moisture and heat resistance, and is suitable for low-temperature punching operation.

4.Fiberglass copper clad panel:

Semi curing sheet FR-4:

Jiantao semi curing sheet is obtained by curing E-grade glass cloth impregnated with flame-retardant epoxy resin to "B" stage under precise temperature and weight control, which makes it have stable rheological properties in the manufacturing process of multilayer PCB.

KB-7150 CEM-3:

It is a kind of composite base copper-clad laminate, which can replace FR-4 for single / double-sided circuit board. It has good machinability, reliability of metallized hole, moisture resistance and heat resistance.

KB-6167 FR-4:

It is an epoxy glass cloth based copper clad plate with excellent heat resistance and mechanical properties. It can be used as PCB with high density and excellent heat resistance.

4.PCB material selection

In the lead-free electronic assembly process, due to the temperature rise, the degree of bending occurs when the printed circuit board is heated increases, so in SMT, it is required to use plates with small bending degree as far as possible, such as fr-4 and other types of substrate. Due to the influence of expansion and shrinkage stress on the element after the substrate is heated, electrode stripping will be caused and reliability will be reduced. Therefore, it is necessary to pay attention to the material expansion coefficient when selecting materials, especially when the element is larger than 3.2×1.6mm. Surface mount technology is used in PCB for high thermal conductivity, excellent heat resistance (150 ℃, 60 min) and weldability (260 ℃, 10 s), high (more than 1.5 x 104 pa) copper foil adhesive strength and bending strength (25 x 104 pa), high conductivity and dielectric constant, good cutting precision (+ / - 0.02 mm) and the compatibility with cleaner, additional requirements appearance smooth level off, not warp, crack, scars and rusty spot, etc.

5.Drilling to choose:

With the rapid development of SMT SMT technology, the multilayer circuit board needs to conduct between, through the electroplating after drilling to ensure, which requires a variety of drilling equipment. To meet the above requirements, at present, at home and abroad to promote different performance of PCB CNC drilling equipment. The production process of printed circuit board is a complex process, which involves a wide range of processes, mainly involving the fields of photochemistry, electrochemistry, thermochemistry; There are also many process steps involved in the manufacturing process. The example of hard multilayer circuit board is used to illustrate the processing process. Drilling is very important in the whole process working procedure, hole processing, with the longest holding time is also the location precision of hole and the hole wall quality directly affect the subsequent hole metallization and SMT process, also directly affect the machining quality and the cost of printed circuit board nc drilling machine principle, structure and function on the PCB drilling method is often used with CNC machinery drilling method and laser drilling method, etc., at this stage to mechanical drilling method most used.st3