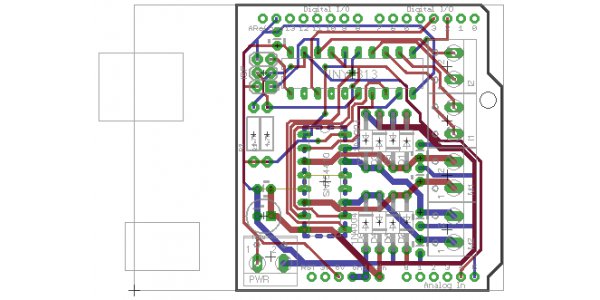

PCB is divided into single-sided, double-sided and multilayer boards. The important processes of printing PCB: Printing the Copper for the Interior Layers - Getting Rid of the Unneeded Copper - Inspection and Layer Alignment - Laminating the PCB Layers - Drilling - PCB Plating - Imaging and Plating the Outer Layer - The Last Etching - Applying the Solder Mask - Finishing PCB and Silkscreening - Electrical Reliability Testing - Cutting and Profiling.

1. The concept of "Layer"

Protel's "layers" are not virtual, but the actual copper foil layers of the PCB material itself. PCB not only has upper and lower sides for routing, but also has interlayer copper foil that can be specially processed in the middle of the board. Because these layers are relatively difficult to process, most of them are used to set the power wiring layers with simpler wiring (such as Ground Dever and Power Dever in software), and usually use large area filling methods to route (such as ExternaI Plane and Fill in software). Where the upper and lower surface layers need to communicate with the middle layers, the so-called "vias" mentioned in the software are used to communicate. With the above explanation, it is not difficult to understand the concepts of "multi-layer pads" and "wiring layer settings". Many people have completed the wiring. Only when they were printed did they find that there were no pads on the wired terminals. In fact, when they added the device library, they ignored the concept of "layers" and did not define the characteristics of the pads they drew Multi-layer. It should be reminded that once the number of layers of the printing plate is selected, it is necessary to turn off those unused layers.2. Vias

In order to connect the lines between the layers, a common hole is drilled at the intersection of the wires that need to be connected at each layer, which is a via. In the process, a layer of metal is plated by chemical deposition on the cylindrical surface of the hole wall of the via to connect the copper foils that need to be connected in the middle layer. The upper and lower sides of the via are made into ordinary pad shapes, which can be directly connected with the upper and lower lines, or it can be disconnected. In general, the following principles apply to the handling of vias when designing circuits:2.1 Minimize the use of vias. Once a via is selected, it is necessary to handle the gap between it and surrounding entities, especially the gap between the lines and vias that are not easily connected to the vias in the middle layer. For automatic routing, you can select "on" in the Via Minimizition submenu to solve it automatically.

2.2 The larger the required ampacity, the larger the required via size. For example, the vias used to connect the power and ground layers to other layers will be larger.

3. Silk screen layer (Overlay)

In order to facilitate the installation and maintenance of the circuit, the required logo patterns and text codes are printed on the upper and lower surfaces of the printed board, such as component labels and nominal values, component outline shapes and manufacturer's marks, production dates, and so on. Characters must not be blocked by components, do not invade the soldering area and be wiped off, and do not place component labels on adjacent components.4. Specificity of SMD

There are a large number of SMD packages in the Protel package library, namely surface-mount devices. In addition to their small size, the biggest feature of this type of device is the single-sided distributed element pin hole. Therefore, when choosing this kind of device, it is necessary to define the side of the device to avoid "Missing Pins". In addition, the related text labels of such components can only be placed along the side of the component.5. Grid Filled Area (External Plane) and Filled Area (Fill)

The grid-shaped filling area (External Plane) is to process a large area of copper foil into a mesh shape, and the filling area (Fill) is only a complete retention of the copper foil. The former has a strong function of suppressing high-frequency interference in circuit characteristics, and is suitable for places where large areas need to be filled, especially when certain areas are used as shielded areas, divided areas or high-current power lines. The latter is mostly used for general line ends or turning areas where small areas need to be filled.6. Pad

Pads are the most common and important concept in PCB design. When selecting the pad type of a component, factors such as the shape, size, arrangement form, vibration and heat conditions, and direction of the force must be taken into consideration. Protel provides a series of pads of different sizes and shapes in the package library, such as round, square, octagonal, round square, and positioning pads, but sometimes this is not enough and you need to edit it yourself. For example, pads that generate heat, are stressed, and have large currents can be designed into a "teardrop shape." In general, in addition to the above, you should consider the following principles when editing pads yourself:6.1 When the length of the shape is inconsistent, the difference between the width of the connection line and the specific side length of the pad must not be too large.

6.2 When you need to route between the corners of the component, use asymmetrical pads.

6.3 The size of each component pad hole must be edited and determined according to the thickness of the component pin. The principle is that the size of the hole is 0.2-0.4 mm larger than the diameter of the pin.

7. Various films

These films are not only indispensable in the PCB manufacturing process, but also a necessary condition for component soldering. According to the position of the "film" and its function, the "film" can be divided into two parts: the component surface (or soldering surface) flux film (Top or Bottom) and the component surface (or soldering surface) solder mask (Top or Bottom Paste Mask). As the name suggests, the soldering flux film is a layer of film that is applied to the pads to improve the solderability, that is, the light-colored round spots slightly larger than the pads on the green board. The situation of the solder mask is exactly the opposite. Adapting the board to soldering methods such as wave soldering requires that the copper foil on the non-pads of the board cannot be tinned. Therefore, a coating must be applied to all parts other than the pads to prevent tin from being applied to these parts. It can be seen that these two types of films are a complementary relationship. From this discussion, it is not difficult to determine the settings of items such as "Solder Mask Enlargement" in the menu.8. Flying lead/line

The flying lead has two meanings: a rubber band-like network connection for observation during automatic routing. After the components are imported through the network table and a preliminary layout is made, the network under the layout can be seen using the "Show" command crossover condition of the wiring, and constantly adjust the position of the component to minimize this kind of crossover, in order to obtain the maximum routing rate of automatic wiring. In addition, after the auto-routing is completed, which networks have not yet been deployed, you can also use this function to find out. After finding the un-communicated networks, manual compensation can be used. If the compensation cannot be used, the second meaning of "flying wires" is used, which is to connect these networks with wires on future PCB boards. If the circuit board is produced in large batches of automated lines, this flying lead can be considered as a resistance element with a resistance value of 0 ohms and a uniform pad pitch for design.