SMT Assembly Processing

Posted: May 14, 2022

By: Bonnie

There are two basic processes in the SMT process, one is the solder paste-reflow process, and the other is the paste-wave soldering process. In actual production, it should be selected separately according to the type of components and production equipment used, as well as the demand of the products, or repeated mixing to meet the needs of different product production.

If the above two processes are mixed and reused, it can be evolved into a variety of process industrial electronics assembly, such as hybrid installation.

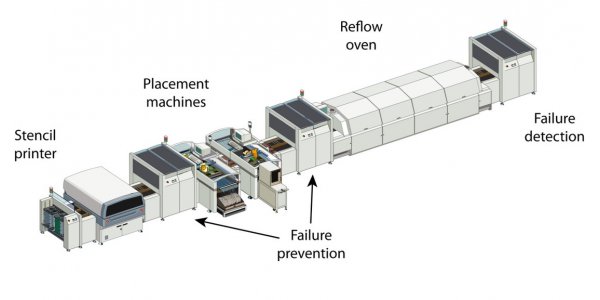

1. Solder paste - reflow soldering process

The process flow is characterized by simplicity and quickness, which is beneficial to the reduction of the volume of the product, and the process flow shows superiority in the lead-free process.2. Patch-wave soldering process

The characteristic of the process is that the space of the electronic product can be further reduced by using the double-panel space, and the through-hole components are partially used, and the price is low, but the equipment requirements are increased, and there are many defects in the wave soldering process, and it is difficult to achieve high-density assembly.If the above two processes are mixed and reused, it can be evolved into a variety of process industrial electronics assembly, such as hybrid installation.

3. Hybrid installation process

The characteristic of the process flow is to make full use of the double-sided space of the PCB, which is one of the methods for minimizing the installation area, and still retains the advantages of low cost of the through-hole components, and is more common in the assembly of consumer electronic products.4. Both sides use solder paste-reflow soldering process

The characteristic of the process is that the double-sided solder paste reflow process can fully utilize the PCB space, which is the only way to minimize the installation area. The process control is complicated and the requirements are strict. It is often used in dense ultra-small electronic products. The mobile phone is one of the typical products. However, this process has been rarely recommended in the SnAgCu lead-free process because secondary soldering heat can cause damage to PCBs and components.

More resources:

Do you have any questions about the above-mentioned? Contact us now, we will reply to you soon.

Is the article useful to you?

No

Yes(

12

)

12

6087

1

Share to: