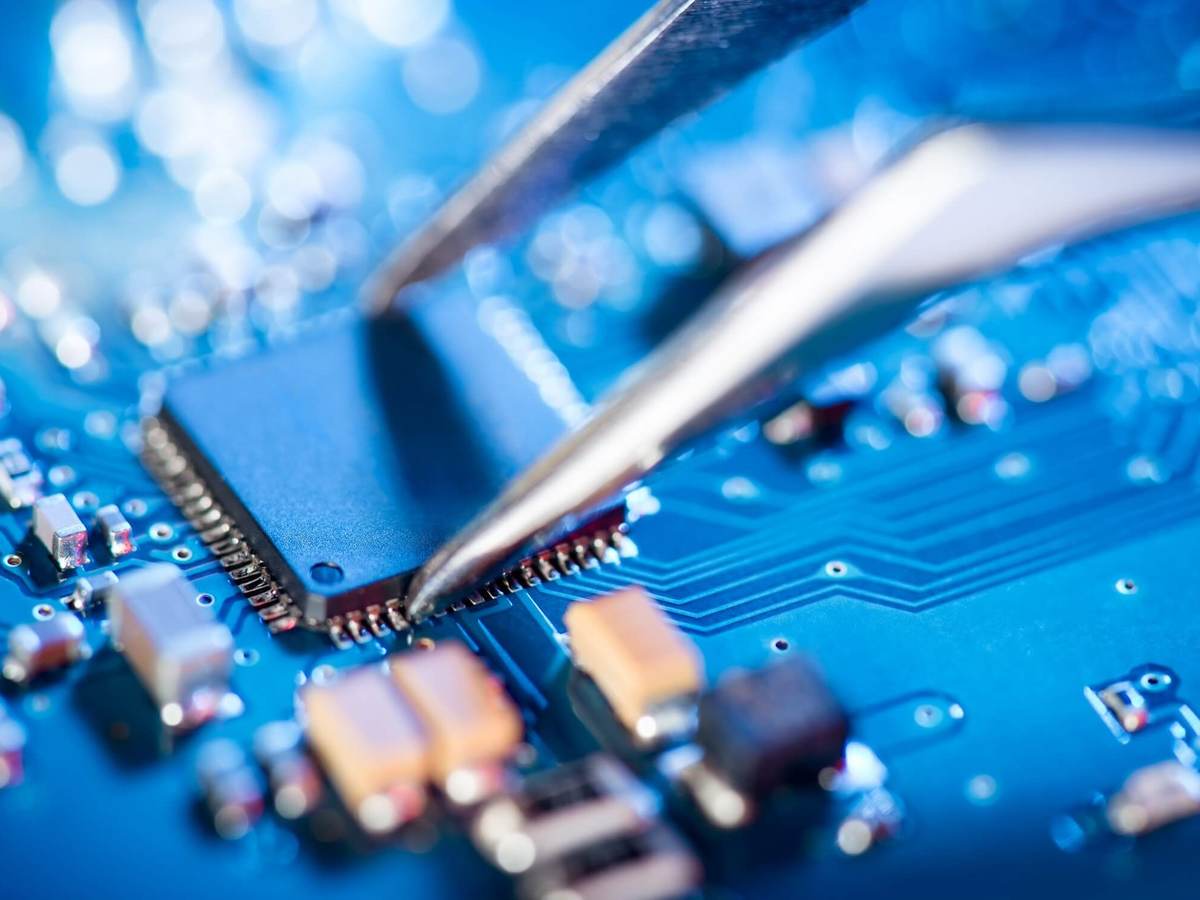

Failure analysis is an important part of the reliability of electronic assembly process. To carry out electronic process failure analysis, it must have certain testing and analysis equipment.

Various analytical equipment has its performance characteristics, application range and sensitivity. According to the requirements and requirements of failure analysis, various analysis techniques and analysis methods are needed to determine the location of failure, the degree of failure, the cause and mechanism of failure. Therefore, failure analysis is related to the analysis theory of many professional knowledge, and also relates to various analysis devices. Analysis experience also plays an important role in failure analysis.

Failure of electronic assembly process analysis Analysis of the failure process of the dunk process, identification of failure modes, description of failure characteristics, assumptions and determination of failure modes, and proposed corrective measures and prevention of new failures.

Smt failure analysis

The failure analysis of the electronic assembly process is to perform post-mortem inspection and analysis on the failure phenomena related to the assembly process, such as solder joints, vias and traces determined to be ineffective according to the performance failure criterion, in order to find and determine the failure associated with the assembly process.

The reason and mechanism to feedback to the design, manufacture and use side, to prevent the recurrence of failure, to achieve the ultimate goal of improving the reliability of electronic products.

The failure analysis of the electronic assembly process is as follows:

1. The theory and method of improving hardware design, process design and reliable application through failure analysis.

2. Through the failure analysis to find the physical phenomenon causing the failure, and obtain the model of reliability prediction.

3. Provide theoretical basis and practical analysis methods for reliability test (accelerated life test and screening test) conditions.

4. When the process problems encountered during the process are determined, determine whether it is a batch problem and provide a basis for whether batch recall and scrapping are required.

5. Corrective measures through failure analysis can improve the yield and reliability of electronic products, reduce the failure of electronic products during operation, and obtain obvious economic benefits.

The techniques and methods for failure analysis of electronic assembly process mainly include: visual inspection, metallographic section analysis, optical microscope analysis technology, infrared microscope analysis technology, acoustic microscope analysis technology, scanning electron microscope technology, electron beam testing technology, X-ray analysis technology and Dyeing and penetration testing techniques, etc.

In the failure analysis application, it is necessary to comprehensively use one or more of these technologies according to the type, phenomenon and mechanism of the failure problem to complete the failure analysis work. This chapter will focus on the principles, methods, and applicable conditions of analytical techniques often used in failure analysis of electronic assembly processes.

The visual inspection is mainly to analyze and inspect the appearance defects. The purpose of the visual inspection is to record the physical dimensions, materials, designs, structures and markings of PCBs, components and solder joints, confirm the damage of the appearance, and detect abnormalities and defects such as pollution. It is evidence of errors, overloads, and operational errors in process manufacturing or applications that are likely to be associated with failure.

Visual inspection is usually performed by visual inspection. It can also be used with a magnifying glass or optical microscope of 1.5 to 10 times. One of the functions of visual inspection is to verify the consistency of PCBs, components and solder joints with process failures with standards and specifications; the second function of visual inspection is to look for problems that may lead to failure.

For example, if there is a crack in the outer casing or the glass insulator, it may be that the external environmental gas enters the inside of the component to cause electrical property change or corrosion. If there is foreign matter between the outer leads, the foreign matter may cause a short circuit between the leads. Mechanical damage on the PCB surface may cause the PVB trace to break and cause an open circuit.

Since the failure analysis may be done by destructive analysis such as slicing and decapsulation, the object of the visual inspection no longer exists. Therefore, it is necessary to take a detailed record when performing the visual inspection, and it is better to take some pictures.

As a preliminary check, valuable information may be lost if the test piece is handled casually before the appearance is checked. As part of this visual inspection program, first record all of its information, that is, record the manufacturer's name, specification, model, batch, date code, etc. of the PCB manufacturer and component manufacturer. Secondly, special attention should be paid to the inspection of the following aspects.

1. Mechanical damage: cracks, scratches, defects from the pins, roots and package seals of electronic components; mechanical damage marks on solder joints and PCB surfaces.

2. Device sealing defects: the joints from the electronic components and glass, ceramic and plastic joints, as well as the root adhesion and sealing seam.

3. Device lead plating defects: uneven coating, bubbles, pinholes and rust from the surface of electronic components.

4. PCB surface contamination or adhesion: mainly from the processing.

5. Thermal damage or electrical damage of the device.

6. PCB delamination and bursting.

7. Abnormality of the surface treatment layer of the PCB.

8. Whether the solder joints have remelted and cracked.

In the reliability design, clear control requirements are required for the production, storage, storage and transportation processes in the process documentation, and the suspicious parts must be further inspected with measuring instruments that can obtain information.

The stereomicroscope has a high degree of microscopic observation and a simple low magnification, and the magnification between the two (about several times to 150 times).

High-magnification metallographic microscope can not only be used for bright field observation, but also for dark field observation and differential interference observation.

The magnification can be from several tens to 1500 times. In addition, if it is necessary to make the scene scene deep, there is a scanning electron microscope with a magnification of several tens to hundreds of thousands of times, and a resolution of from several mm to 15 nm, which is an indispensable device for observing a test piece having a fine structure. All important information is recorded using a microscope and its photographic accessories.