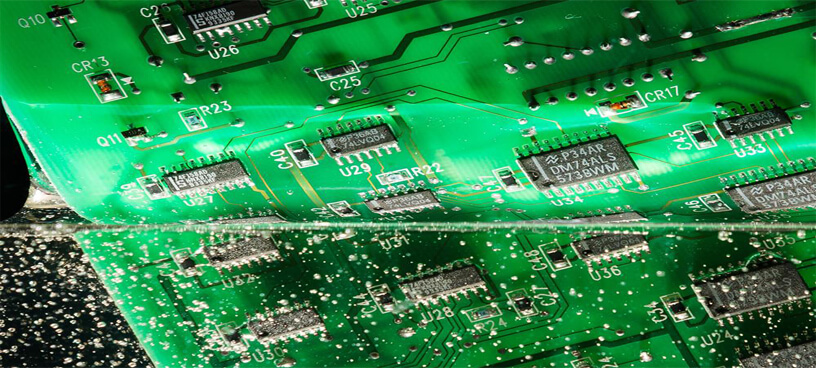

Due to the increasing use of micro-pitch component box BGA devices, the electronics industry has begun using some lead-free surface treatment processes before the lead-free boom.

In addition to HASL, all surface treatments are suitable for tin-lead and lead-free assembly, such as organic solderability protective film (OSP), chemical nickel gold (ENIG), immersion silver and immersion tin.

Because they require a flat surface coating, they can be used to replace the HASL.

These surface treatment processes each have their own advantages and disadvantages, none of which is perfect. HASL has a surface unevenness: some places are not thick enough, and some places are thick, so the tin/lead process is also reducing its use.

People initially chose OSP to replace HASL, but OSP is very brittle and requires special handling.

There may be problems when filling holes and testing on the board, especially after two processes of reflow and wave soldering.

In case. Chemical nickel gold ENIG nickel effectively prevents copper from transferring from the PCB pad to the solder ball package interface: preventing the formation of fragile metal compounds. The microporous or champagne-like bubbles in the mid-immersion silver, as well as the black pads in ENIG, are the focus of attention.

The mechanisms for these defects are different, but one thing is consistent: they are all related to the process control of the final manufacturer of the printed circuit board and are related to the chemical material of the plating.

SMT Lead-free Assembly

Which surface coating is best for lead-free? At present, there is no conclusion yet, and it must be selected according to the actual product needs, and depends on the printed circuit board supplier. In some cases, two surface plating layers may be used. For example, single-sided SMT uses OSP, double-sided boards and mixed (SMT and post-insertion) boards use immersion silver.

If OSP is used, nitrogen or less corrosive fluxes can be used for re-welding and wave soldering, depending on the product. If ENIG is used, nitrogen is not required. The use of nitrogen, the type of flux and sensitivity to cost are important factors in selecting a surface plating.

Compared to the excellent performance of HASL SnPb, there is a problem with lead-free alternative surface treatment. OSP's tin-through performance, ICT test compatibility, chemical tin whiskers and environmental issues have not been properly addressed, and chemical Ag, which has been favored by many companies, has begun to be plagued by Planar Void problems. In 2005, Intel reported the Planar Void phenomenon of chemical silver, and caused the early failure of the solder joint.

The crack propagated through the cavity: further research indicates that the cause is the Cu cavity caused by the variation of the chemical silver process itself, although some Some syrup suppliers claim to have resolved, but endless market accidents indicate that there is currently no good control or prediction method for this variability.