1.0 Surface finish of PCB

1.1 PrincipleAs natural copper tends to exist in the air as an oxide, it is unlikely to remain raw copper for long. Other treatment of copper is therefore required.

The primary purpose of surface treatment is to ensure that the PCB maintains good solderability and electrical properties.

1.3 Package

In package, the designer may use scaling powder to remove the oxide of most copper, but the scaling powder itself is not easy to remove, so designer generally does not use a strong flux.

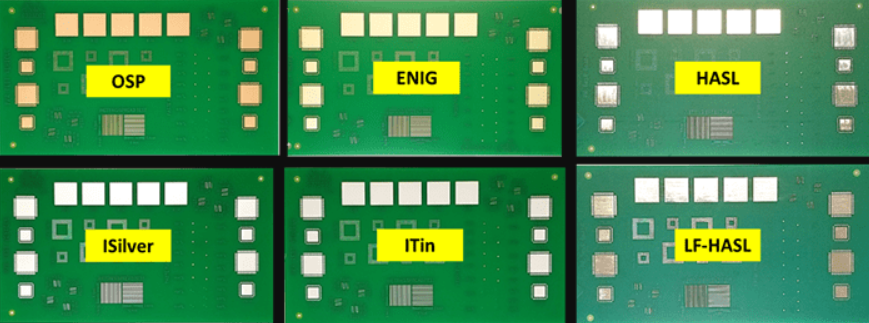

2.0 Common surface finish process

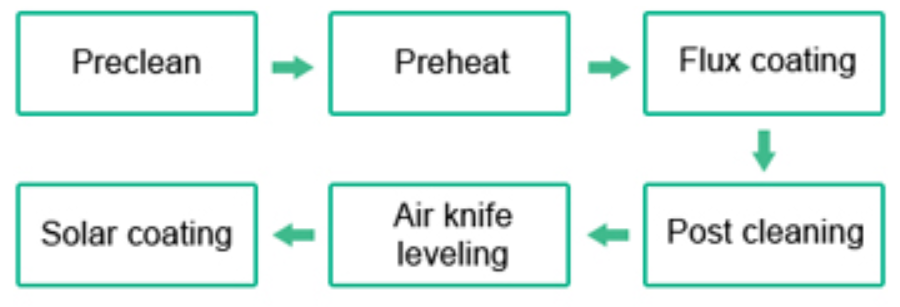

2.1 Lead-free HASL

A coating (lead-free) is formed on the PCB by HASL.

( 6 Processes Compare)

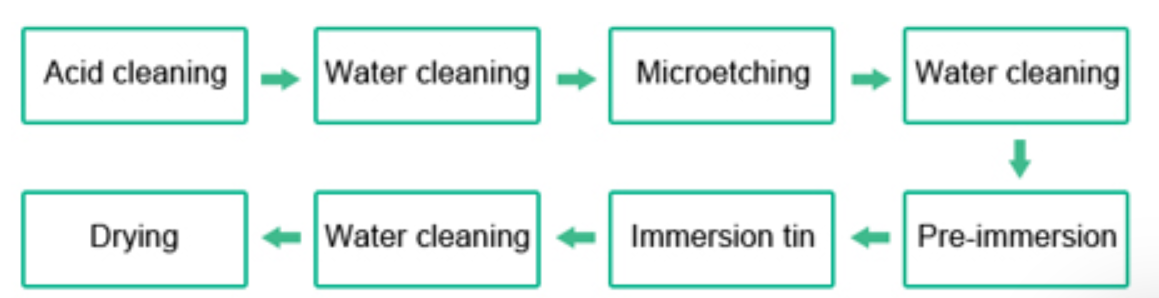

2.2 Immersion Tin (ImSn)Immersion the tin layer into the PCB to make the PCB have good flatness, weldability, and thermal stability. Generally, this type of PCB board storage time is relatively short.

(IMSn Process)

Immersing a silver layer in the PCB. This process is very simple and fast. The main benefit is that the PCB can be reprocessed, and the coating is very thin.

(IMAg Process)

Provides an oxidation resistant and solderable coating (leady) to the PCB by hot drying. This process can be automated, so it has good oxidation resistance and weldability, and its coating is more well-distributed.

(HASL Process)

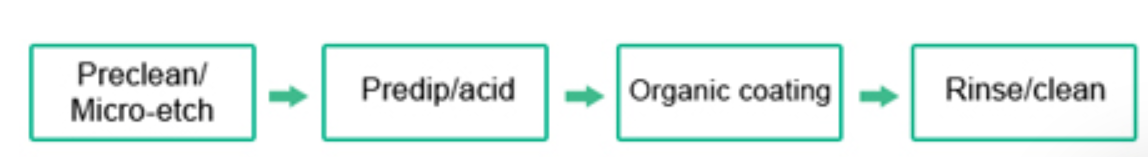

In all the surface treatments, OSP is the cheapest and fastest surface finish process, so its quality is not very well, and it is mostly used for rust protection only.

(OSP Process)

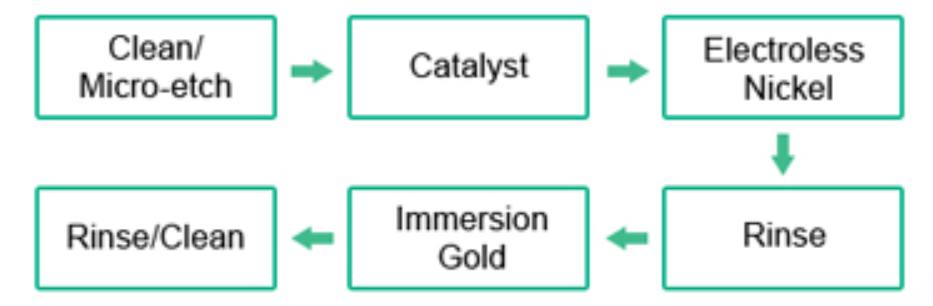

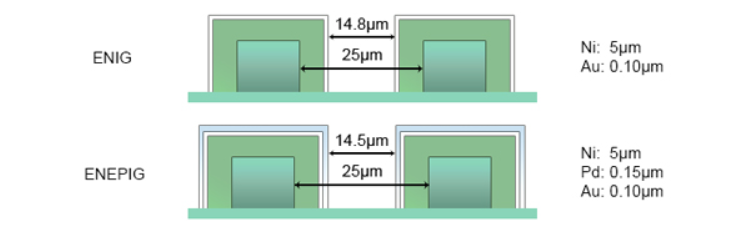

Immersing a gold layer in the PCB. This coating will greatly improve the antioxidant properties of the PCB and will be more beneficial for welding due to the nickel layer. However, this type of PCB will be blackened during welding.

(ENIG)

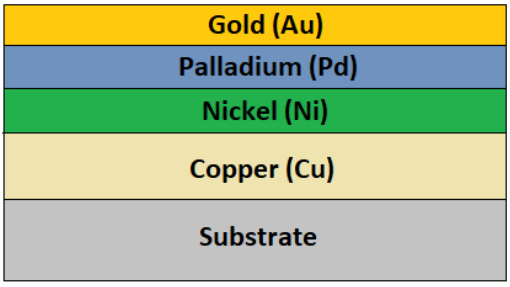

2.7 Electroless Nickel Electroless Palladium Immersion Gold (ENEPIG)

This method has been added some other layers to the ENIG. So, the gold layer Immerse into the PCB, and it means that the PCB will not turn black when welded. And it retains all the advantages of ENIG. But this method is expensive and complex. Designers generally use it only when they have high quality requirements.

3.0 Conditions of the surface finish

3.1 FlatnessWhen the surface of PCB is smooth but uneven, as to ensure PCB performance, weldability, etc. The designer must choose thinner surface treatments (ENIG, ENEPIG, OSP).

3.2 Weldability and wettability

Solderability is always a key factor when designers use PCBS. The finish of certain surface treatments (OSP, ENEPIG) can interfere with weldability, so it should use some process (HASL, ImSn) to improve surface finish level or decrease the influence for the surface finish.

3.3 Gold or aluminum wire bonding

If the PCB requires gold or aluminum wire bonding, the designer must choose either ENIG or ENEPIG.

When using OSP surface treatment, it will destroy the durability of the PCB. Therefore, if the designer needs to consider the storage factor, they need to choose different processing methods (ENIG, ImAg, ENEPIG). PCBs are brittle when the designer keeps the PCB is not safety enough. They all relate to the storage condition of the PCB. Therefore, these will be considered prior to the PCB surface treatment program, and designer will get the less influence from PCB storage factor.

3.5 Processing period

Some PCBs need to be reprocessed to produce the final product. This requires the use of surface treatments that can be reworked (ImAg, ImSn).

3.6 RoHS requirement

Compliance with RoHS environmental standards is critical. In general, surface treatments containing lead do not meet RoHS requirements.

3.7 Other factor

- Production cost

-PCB use environment

-Spacing between PCB layers

-High frequency possibilities (for RF applications)

-Shock and fall resistance

-Temperature

-Throughput and producing speed

4.0 Conclusion

There are many options for PCB surface finish. It is not easy for the designer to choose an appropriate treatment. This means that the choice of PCB surface finish process is critical. Therefore, designers should judge the way of surface treatment according to the actual conditions and various factors affecting PCB. Only in this way can the surface treatment of PCB be guaranteed to be the most reasonable.