How Manufacturing Factory Produce a PCBA

Posted: May 14, 2022

By: Bonnie

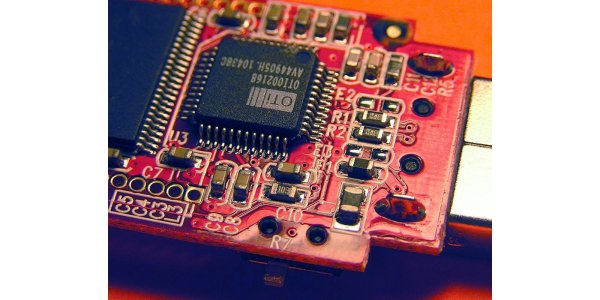

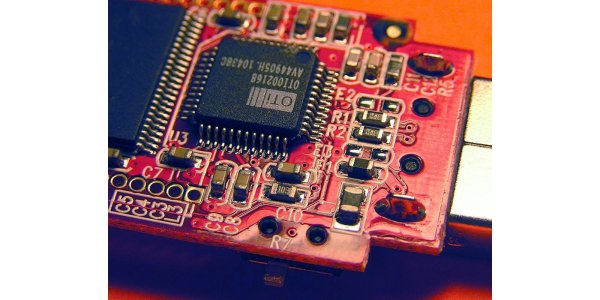

At present, the assembly of circuit boards is basically soldering electronic components to printed circuit boards through solder. This soldering process can be performed by surface mount technology (SMT) or wave soldering. Of course, you can also use all hand welding, but the quality of hand welding is very risky, and it cannot be mass produced.

Because wave soldering has few products in use, this article only introduces surface-mount soldering (SMT) for circuit board assembly soldering. Basically, the current SMT manufacturing process is a one-stop operation, that is, the empty board is placed on the SMT production line, and the final board outflow and assembly is completed, all in the same line.

Because wave soldering has few products in use, this article only introduces surface-mount soldering (SMT) for circuit board assembly soldering. Basically, the current SMT manufacturing process is a one-stop operation, that is, the empty board is placed on the SMT production line, and the final board outflow and assembly is completed, all in the same line.

The following process will briefly introduce the loading process from empty board to board assembly, as well as the post-process of quality assurance.

Generally, the traditional pick and place machine uses the principle of suction to move electronic parts, so there must be a flat surface on the top of these electronic parts for the nozzle of the machine to pick up parts. For some electronic parts, there is no plane left for these machines. At this time, special nozzles need to be customized for these special-shaped parts, or a layer of flat tape is attached to the parts, or wear a flat cap.

In addition, some SMT of mobile phone boards will also be designed with an AOI before the reflow furnace to confirm the quality before reflow. Sometimes, it is because the shield frame is stamped on the part, AOI cannot be used to check solderability after reflow oven.

Basically, after the circuit board passes through the reflow furnace, the entire circuit board is assembled. If there are exceptions to hand soldering, the rest is to check and test the circuit board for defects or malfunctions.

Therefore, if only AOI is used to replace ICT, there is still some risk in quality, but ICT is not 100%. It can only be said that the test coverage rate is made up for each other.

Many factories will provide visual inspection templates at this station to facilitate visual inspection personnel to check some key parts and part polarity.

When welding parts by hand, some fumes will be generated. These fumes will contain a lot of heavy metals, so it is necessary to set up fume exhaust equipment in the operation area, and try not to let the operator inhale these harmful fumes. It should be reminded that some parts will be arranged at a later stage due to the needs of the process.

The circuit test machine is divided into advanced and early stage machines. The preliminary test machine is generally called MDA (Manufacturing Defect Analyser), and its function is to measure the basic characteristics of electronic parts and open and short circuit as mentioned above.

In addition to all the functions of the initial model, the high-level test machine can also send power to the board under test, start the board under test, and execute the test program. The advantage is that it can simulate the function of the circuit board under actual startup. The test can partially replace the later function test machine (Function Test). However, the test fixture of such a high-level test machine is 15 to 25 times higher than an initial test fixture, so it is generally suitable for mass production products.

The following process will briefly introduce the loading process from empty board to board assembly, as well as the post-process of quality assurance.

1. Bare Board Loading

The first step in the assembly of the circuit board is to arrange the bare boards neatly, then place them on the magazine, and the machine will automatically feed the boards one by one into the SMT production line.2. Solder paste printing

The first step for a printed circuit board (PCB) to enter the SMT production line is to print a solder paste. Here, the solder paste is printed on the pads of the parts that need to be soldered. These solder pastes melt when they pass through a high-temperature reflow oven and solder electrical parts onto the circuit board.3. Solder paste inspector (option)

Since the quality of solder paste printing is related to the quality of the subsequent parts soldering, some SMT factories will first check the quality of the solder paste printing with optical instruments after the solder paste is printed for quality stability. If there is a poorly printed board, remove it, wash off the solder paste on it and reprint it, or remove excess solder paste by repairing it.4. Pick and Place speed machine

Here, some smaller electronic parts (such as small resistors, capacitors, and inductors) will be hit on the circuit board. These parts will be slightly stuck by the solder paste just printed on the circuit board. Very fast, almost like a machine gun, and the parts on the board are not yet scattered, but large parts are not suitable for use in fast machines, which will slow down the speed of small parts that were originally fast. Secondly, the parts will shift from the original position due to the rapid movement of the board.5. Pick and Place general machine

Also known as slow speed machine, here will be to play some relatively large electronic parts, such as BGA IC, connector (connector), etc. These parts need a more accurate position, so alignment is very important. Use the camera to check the position of the parts, so the speed is much slower. The parts here may not always have tape-on-reel packaging because of their size. Some may be Tray or tube packaging. However, if the SMT machine can eat trays or tubular packaging materials, an additional machine must be configured.Generally, the traditional pick and place machine uses the principle of suction to move electronic parts, so there must be a flat surface on the top of these electronic parts for the nozzle of the machine to pick up parts. For some electronic parts, there is no plane left for these machines. At this time, special nozzles need to be customized for these special-shaped parts, or a layer of flat tape is attached to the parts, or wear a flat cap.

6. Hand place component or visual inspection

When all the parts are printed on the circuit board, before going through the high temperature reflow furnace, a check point is usually set to pick out the offset or dropped parts, because after the high temperature furnace, if there is still a problem must be moved to the iron, which will affect the quality of the product, and there will be additional costs; other large electronic parts or traditional parts of DIP or for some special reasons, cannot be passed / Placement machine to operate the parts, but also manually place the parts here.In addition, some SMT of mobile phone boards will also be designed with an AOI before the reflow furnace to confirm the quality before reflow. Sometimes, it is because the shield frame is stamped on the part, AOI cannot be used to check solderability after reflow oven.

7. Reflow furnace

The purpose of the reflow furnace is to melt the solder paste and form a common gold (IMC) on the part feet and the circuit board, that is, solder the electronic parts on the circuit board. The temperature profile of its temperature rise and fall often affects the quality of the entire circuit board soldering. According to the characteristics of the solder, a general reflow furnace will set a preheat zone, a wetting zone, a reflow zone, and a cooling zone. With the current lead-free SAC305 solder paste, its melting point is about 217 ° C, which means that the temperature of the reflow furnace must be at least higher than this temperature to remelt the solder paste. In addition, the highest temperature is best not to exceed 250 ° C, otherwise many parts will be deformed or melted because they cannot withstand such a high temperature.Basically, after the circuit board passes through the reflow furnace, the entire circuit board is assembled. If there are exceptions to hand soldering, the rest is to check and test the circuit board for defects or malfunctions.

8. Optical Inspection Solder (AOI, Auto Optical Inspection) Option

It is not necessary that every SMT production line has an optical inspection machine (AOI). The purpose of setting AOI is because some circuit boards with too high density cannot perform subsequent open and short circuit electronic tests (ICT), so AOI is used instead, but Because AOI has its blind spots for optical interpretation, for example, the solder under the part cannot be judged. At present, it can only be checked whether the part has a tombstone or side, missing part, displacement, polarity direction, tin bridge, air soldering, etc. However, it is impossible to judge the quality of parts such as fake soldering, BGA solderability, resistance value, capacitance value, and inductance value, so there is no way to completely replace ICT so far.Therefore, if only AOI is used to replace ICT, there is still some risk in quality, but ICT is not 100%. It can only be said that the test coverage rate is made up for each other.

9. Unloading

After the board is assembled, it will be retracted to the magazine, which has been designed to allow the SMT machine to automatically pick and place the board without affecting its quality.10. Visual Inspection

Whether or not an AOI station is set up, the general SMT line will still set up a visual inspection area of the circuit board to check whether there are any defects after the circuit board is assembled. If there is an AOI station, the visual inspector still needs to check some places that can't be read by AOI, or check the AOI for bad results.Many factories will provide visual inspection templates at this station to facilitate visual inspection personnel to check some key parts and part polarity.

11. Touch up

If some parts cannot be made with SMT, touch-up hand-welded parts are needed, which is usually placed after the inspection of the finished product to distinguish whether the shortcomings are from SMT or the subsequent process. Use iron and solder wire for the back-up parts. When soldering, the soldering iron maintained at a certain high temperature will contact the foot of the part to be soldered until the temperature rises to a temperature sufficient to melt the wire, and then add tin. The wire melts, and after the tin wire cools, the parts are soldered to the circuit board.When welding parts by hand, some fumes will be generated. These fumes will contain a lot of heavy metals, so it is necessary to set up fume exhaust equipment in the operation area, and try not to let the operator inhale these harmful fumes. It should be reminded that some parts will be arranged at a later stage due to the needs of the process.

12. Circuit board open / short test (ICT, In-Circuit Test)

The purpose of ICT settings is mainly to test whether the parts and circuits on the circuit board are open or shorted. It can also measure the basic characteristics of most parts, such as resistance, capacitance, and inductance values, to determine whether these parts have passed the high temperature reflow furnace. Whether the function is damaged, wrong, missing, etc.The circuit test machine is divided into advanced and early stage machines. The preliminary test machine is generally called MDA (Manufacturing Defect Analyser), and its function is to measure the basic characteristics of electronic parts and open and short circuit as mentioned above.

In addition to all the functions of the initial model, the high-level test machine can also send power to the board under test, start the board under test, and execute the test program. The advantage is that it can simulate the function of the circuit board under actual startup. The test can partially replace the later function test machine (Function Test). However, the test fixture of such a high-level test machine is 15 to 25 times higher than an initial test fixture, so it is generally suitable for mass production products.

13. Circuit board function test

The function test is to make up for the shortcomings of ICT, because ICT only tests the open and short circuits on the circuit board, and other functions such as BGA and products have not been tested, so you need to use the function test machine to test all the functions on the circuit board.14. Assembly board de-panel

Generally, circuit boards are panelized to increase the efficiency of SMT production. There are usually so-called one-in-one boards, such as two-in-one (2 in 1) and four-in-one (4 in 1). After all the assembly operations are completed, it is necessary to de-panel it into a single board. Some circuit boards with only a single board also need to be cut off some extra board edges (break-away).There are several ways to cut the circuit board. You can design a V-cut using a blade cutting machine (Scoring) or direct manual folding (not recommended). More sophisticated circuit boards will use a path splitter cutting machine (Router). It will not hurt electronic parts and circuit boards, but the cost and working hours are longer.

More resources:

Do you have any questions about the above-mentioned? Contact us now, we will reply to you soon.

Is the article useful to you?

No

Yes(

12

)

12

272

1

Share to: